In an optimistic scenario, the need for smoother clinical workflows, faster turnaround times, and fewer dental appointments could boost market growth. Dentists may be more likely to invest in technologies like CAD/CAM and dental 3D printing to reduce the time taken to deliver dental appliances and treatment, and patients may be more likely to opt for these solutions for the same reason.

Dental caries or tooth decay is a common ailment across all age groups, with the global incidence of decayed and missing teeth (DMT) increasing dramatically in recent years. According to the CDC, in 2019, 64.9% of adults aged above 18 years of age had a dental examination or dental cleaning procedure.

According to the American College of Prosthodontists, more than 36 million Americans are completely edentulous, and around 120 million Americans are missing at least one tooth. As dental implants, dental prosthetics, and other dental products manufactured by dental 3D printers find high use in the restoration of the dental structure, the high incidence of target diseases will play a key role in the growth of the dental 3D printing market during the forecast period.

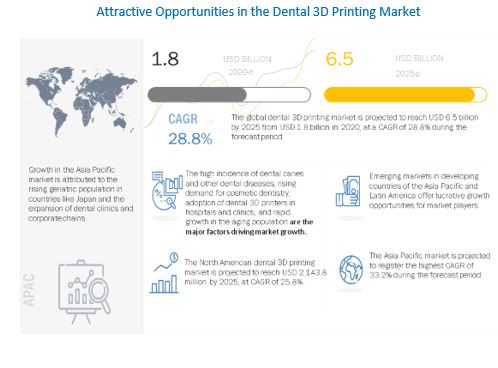

The dental 3D printing market is projected to reach USD 6.5 billion by 2025 from USD 1.8 billion in 2020, at a CAGR of 28.8%. The dental 3D printing medical devices market is primarily driven by factors such as the high incidence of dental caries and other dental diseases, rising demand for cosmetic dentistry, the growing adoption of dental 3D printers in hospitals and clinics, and rapid growth in the geriatric population.

For More Information Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=258228239

There is a dearth of training programs available for additive manufacturing and a wide gap between academia and practical applications in the industry that is difficult to bridge. The lack of a well-qualified workforce would restrain the overall adoption of dental 3D printing.

The use of CAD/CAM also reduces the need to wear temporary bridges/crowns during the course of the treatment and the number of doctor visits, thereby reducing the cost of dental restoration. Although the majority of prosthetic elements are still made manually, the use of CAD/CAM associated with 3D printing continues to increase due to its advantages.

The cost of a high-resolution 3D printer is around USD 40,000 to USD 100,000. This also makes it difficult for laboratories dependent on federal funding (for whom securing funds in itself is a time-consuming process) to install and use such equipment. Due to this financial aspect, many smaller dental clinics may choose to outsource production to service bureaus or laboratories. This is poses a major challenge to the growth of the dental 3D printing market.