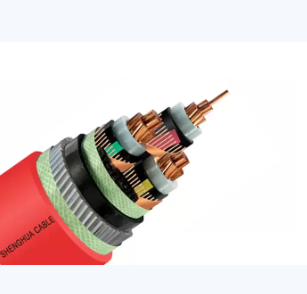

concept of low smoke zero halogen cable

Low smoke zero halogen cable refer to environmentally friendly cables that are made of compounds that do not contain halogens (F, Cl, Br, I, At) and environmental substances such as Pb,Cd,Cr,Hg etc., and do not emit toxic fumes when burned. The outer layer is covered with an armored cable mechanical protection layer to increase the tensile strength, compressive strength, corrosion resistance, etc. of the cable, and protect and prolong the service life. It is a cable designed for areas susceptible to mechanical damage and corrosion. .

Characteristics and uses of low smoke zero halogen cable

- The tensile strength is greater than that of general PVC wires: the tensile strength of general PVC wires is greater than 1.05Kgf/mm2, while the tensile strength of low-smoke halogen-free wires is greater than 1.2Kgf/mm2;

- Has good weather resistance (-30℃~105℃);

- Have good softness (hardness is 80-90);

- Non-migrating (because no plasticizer is added to this product formula, there will be no migration);

- No toxic black smoke will be produced when burning (a small amount of white smoke will be produced);

- Has a high volume resistivity: PVC wires are generally 1012~1015Ω/cm3, and low-smoke halogen-free wires are greater than 1016Ω/cm3;

- Has good high-voltage resistance characteristics: PVC wires are generally resistant to more than 10KV, while low-smoke halogen-free wires are as high as 15KV or more;

- Has good elasticity and viscosity.

low smoke zero halogen cable are widely used. Due to their superior flame retardant properties, little smoke during combustion, and no corrosive gas escape, they are widely used in nuclear power plants, subway stations, telephone exchanges and computer control centers, high-rise buildings, hotels, Radio and television stations, important military facilities, oil platforms, etc., as well as places with a high concentration of people and low air density

The development trend of low smoke zero halogen cable

With the progress of society and the rapid development of science and technology,The inherent weaknesses of PVC are becoming increasingly apparent.When PVC burns, it releases a lot of smoke, serious corrosive gases and toxic gases . Since then, evaluating and finding alternatives to PVC materials has become the focus of debate. Low smoke zero halogen cable and cable because of its low-halogen and low-smoke characteristics.low smoke zero halogen cable are gaining popularity.When a fire occurs, the spread speed is slow, the smoke concentration is low, the visibility is high, and the release of harmful gases is small, which is convenient for personnel to evacuate. The corrosiveness of the combustion gas is small, and the damage to the equipment is also avoided, thereby prolonging the service life of the cable. In order to adapt to the concept of safe and environmentally friendly development, low smoke zero halogen cable have gradually become the first choice for industrial life cables.