Copper clad aluminum wire description

Copper clad aluminum wire refers to a wire with aluminum core wire as the main body and a certain proportion of copper layer plated on the outside. It can be used as a conductor for coaxial cables and wire and cable conductors in electrical equipment.Copper clad aluminum wire is a composite material, and copper-clad aluminum wire can be widely used in cable television signal transmission, large-capacity communication network signal transmission, control signal cables, light vehicle cables, welding cables, emergency mobile cables, etc.

Copper clad aluminum wire covered with welding manufacturing technology, high-quality copper cladding concentrically on the outer surface of the aluminum rod or steel wire core wire, and the formation of a strong metallurgical bond between the atoms between the copper layer and the core, so that two different metal materials combined into an integral whole, can make as drawing and annealing process as a single metal wire drawing process of copper and aluminum with adjustable proportion to the copper layer volume ratio remained relatively constant constant.This Copper clad aluminum wire can not only take advantage of the small specific gravity of aluminum, but also improve the welding performance.

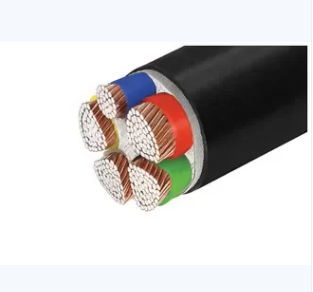

Structure of copper clad aluminum wire

Copper clad aluminum wire consists of copper-clad aluminum conductor, XLPE or PVC insulation, and PVC or polyolefin sheath. Different numbers of cores have different colors, two-core including red and blue, three-core including blue, black and brown, four-core including yellow/green, blue, black and brown, or according to customer requirements.

Copper clad aluminum wire Features

1, DC resistivity: copper clad aluminum wire copper line resistivity large than about 1.5 times the copper wire, the female values are the same, copper clad aluminum wire copper wire weighs about 1/2.

2, The use of copper clad aluminum conductor can be continued for many years to meet the current in the wire and cable product selection, design, installation and other habits, also pressed the cable terminals, enabling soldering.

3, Lower AC resistance:

4, Light weight and low cost: Compared with the same technical specifications of copper cable, copper clad aluminum conductor cable cost savings of more than 40%, copper clad aluminum / copper composite conductor cable cost savings of more than 20%.

5, Good weldability: copper clad aluminum wire because of its surface coated with a layer of concentric copper, with copper wire so it has the same weldability, to facilitate the production

Most of the copper clad aluminum wires are produced by the internationally advanced cladding welding process. The copper layer is made of high-purity refined copper with high density and good electrical conductivity, which realizes metallurgical bonding with the aluminum core wire, and has good adhesion; the copper layer is uniformly distributed along the circumferential direction and longitudinal direction, and has good concentricity.