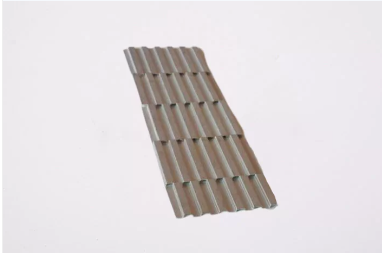

Aluminum fin plate overview

Aluminum fin plate is the most widely used heat exchange equipment in gas and liquid heat exchanger. The purpose of heat transfer enhancement is achieved by adding fins on the ordinary base tube. The base pipe can be steel pipe; Stainless steel pipe; Copper pipe, etc. The fins can also be made of steel strip; Stainless steel strip, copper strip, aluminum strip, etc.

Aluminum fin plate is mainly used for air heating in the drying system. It is the main equipment in the hot air device. The heat medium used by the radiator can be steam or hot water or heat transfer oil. The working pressure of steam generally does not exceed 0.8MPa, and the temperature of hot air is below 170 ℃.

Aluminum fin plate overview application scenarios

Some people say that the alkaline water quality of the current heating system is the root cause of affecting the aluminum fin plate, which is inappropriate, unscientific, and unobjective. The Achilles heel of the aluminum fin plate is that it is most afraid of alkaline water corrosion, which is due to its metallicity. Any material has its applicable conditions, and the aluminum fin plate has clear conditions of use: it is only suitable for neutral hot nickel water with PH=5-8. By grasping this fundamental point, we can handle all kinds of wishes: direct water supply to boilers mostly used in the north, PH=10-12, cannot be used. Second, for the secondary hot water supply after heat exchange, PH=5-8, available; for independent heating systems using gas wall-hung boilers in the south and north, neutral water PH=5-8, available. For hot water beyond this range, only copper, stainless steel or steel and composite aluminum fin plate can be used. aluminum fin plate with internal corrosion of the paint are also available, but not guaranteed.

Aluminum fin plate features advantages

- Super plasticity: The aluminum fin plate is light in weight and high in strength, and can be extruded into various shapes according to the customer's heat dissipation requirements.

- Long service life: The aluminum fin plate has good corrosion resistance, small deformation and strong fire resistance, and the service life can reach 50-100 years.

- Oxidation resistance: The aluminum fin plate profile has been treated by various processes, and the surface has a protective film that resists acid and alkali erosion, which is not easy to be polluted by air, and can maintain its inherent color and luster for a long time.

- Low cost: When the center distance of the radiator inlet and outlet and the heat conduction temperature are the same, the heat dissipation of the aluminum radiator is 2.5 times higher than that of the cast iron radiator. If the heating cover is not added, the heat loss can be reduced by more than 30%, and the cost can be reduced by more than 10%.

With the development of national economy and the improvement of people's living standart, the scope of heating is constantly expanding. The south, where most of the heating was not used before, also generally increased the demand for heating. Now is a good period for the finned radiator market, and the rapid development of cast aluminum finned radiators just catches up with this good period. Aluminum fin parts supplier - Sanqian Technology Co., Ltd. provides high quality aluminum fin parts and aluminum fins. If you have relevant needs, you can browse the company's official website to purchase.