Wire rod mill-laying head overview

Wire rod mill-laying head generally refers to a wire rod mill with a maximum rolling speed higher than 40m/s, which is a comprehensive product of metallurgical technology, electronic control technology and mechanical manufacturing technology. In a high-speed wire rod production line, after the wire rod is rolled, it needs to be laid into a loop through a laying machine to complete the transformation from a straight wire rod to a coil. The Wire rod mill-laying head is one of the key equipment for the production of high-speed wire rods, and it is also an important bottleneck restricting the further speed-up of the high-speed rolling mill. The quality of laying wire directly affects the physical quality of the high-speed wire rod. With its special shape structure and a certain speed, the Wire rod mill-laying head turns the straight current wire rod moving at high speed into a coil with stable coil shape and uniform spacing. With the increase of wire rolling speed and output, the requirements for Wire rod mill-laying head are also getting higher and higher. Therefore, many high-speed wire rod manufacturers will experience unstable laying circles during production, which will affect product quality and production. .

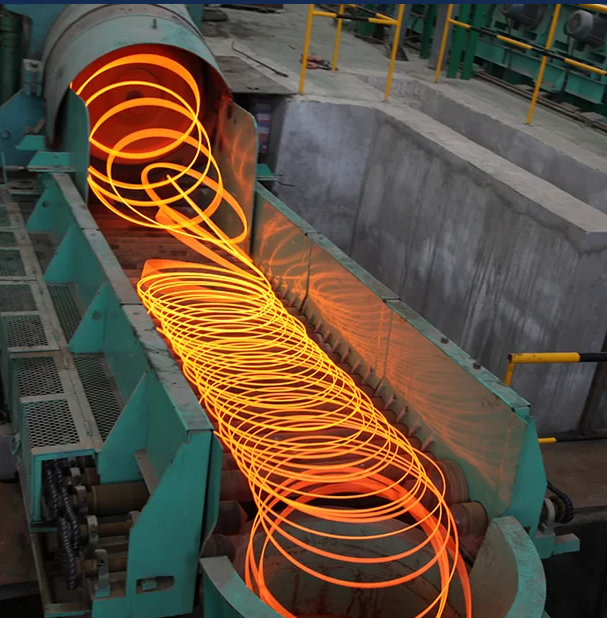

Wire rod mill-laying head principle

The Wire rod mill-laying head is a horizontal structure, which is located between the water-cooled box and the cold-controlled roller table that controls the cooling line after the finishing mill. The Wire rod mill-laying head consists of a transmission device, a hollow shaft, a laying disc, a laying tube, a bevel gear and other components. The laying head is driven by a motor, and the hollow shaft is driven to rotate through the meshing of a pair of bevel gears in the gearbox. The laying tube is installed on the laying disc, and the laying disc and the hollow shaft are connected by bolts.

When the Wire rod mill-laying head is working, it is fed into the hollow shaft of the laying machine from the inlet conduit of the laying machine through the pinch roller in front of the laying machine. The wire is spit out the coil along the tangential direction of the circumference of the spinning tube outlet through the rotating laying tube, and is smoothly poured on the air-cooled roller table to form a continuous coil. When the wire rod passes through the high-speed rotating laying tube, under the action of the positive pressure of the laying tube wall, the sliding friction force, the thrust of the finishing mill and the pinch roll, and its own centrifugal force, it gradually bends and deforms with the shape of the laying tube. , there is a linear motion to gradually bend, and the required curvature is achieved at the exit of the spinning tube to form a spiral coil, which is evenly and smoothly spit out in a circle.

High-speed wire rod production has higher requirements on the shape of spinning circle, and the quality of spinning directly affects the rhythm of production. The spinning process of the spinning machine is relatively complicated. When the spinning condition is not good, it is necessary to carefully observe the displayed situation, carefully check, detect and carefully record the adjustment. Through the understanding of the spinning process, find out the reason and processed in a timely manner.