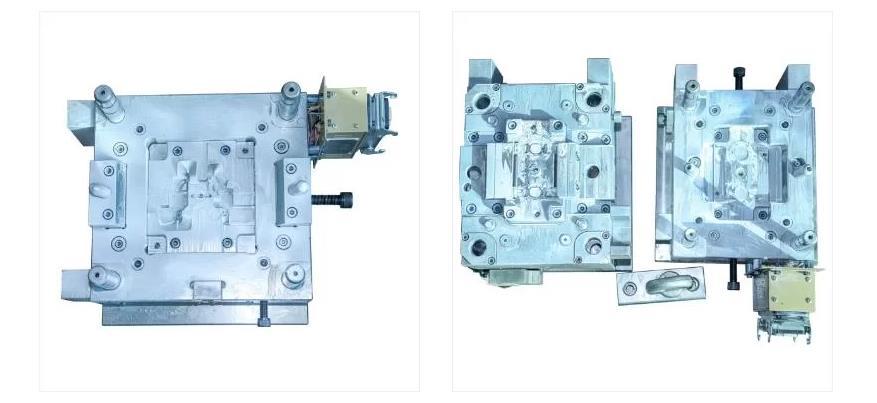

Camera Bracket Mould Maintenance During mould Loading

(1) Clean the upper and lower surfaces of the mould before assembly to ensure that the mounting surface of the mould and the working surface of the press will not be crushed and the parallelism of the upper and lower mounting surfaces of the mould in production.

(2) After the mould is installed, open the mould and clean all parts of the mould, especially the guiding mechanism, and the surface parts mould, clean the surface to ensure the quality of the parts.

(3) Lubricate the sliding parts of the mould and apply grease. Check all parts of the mould, especially the safety parts. Such as safety side pins, safety screws, side shields, punching waste channels, etc.

Camera Bracket Mould Maintenance In Production

(1) Periodically oil the corresponding part of the mould during production. Such as the pressure circle and round corner of the drawing die; the knife mouth part of the trimming die; the part of the flap knife block, etc.

(2) Regularly clean up the small hole waste channel of the trimming punching die.

Camera Bracket Mould Post-Production Maintenance

(1) The mould should be thoroughly inspected after production.

(2) The mould is thoroughly cleaned and wiped to ensure its cleanliness of the mould.

(3) Clean up the scrap in the mould and make sure there is no scrap in the scrap box.

(4) Feedback on the status of the mould and the condition after use to the mould summons truthfully.

Related News: