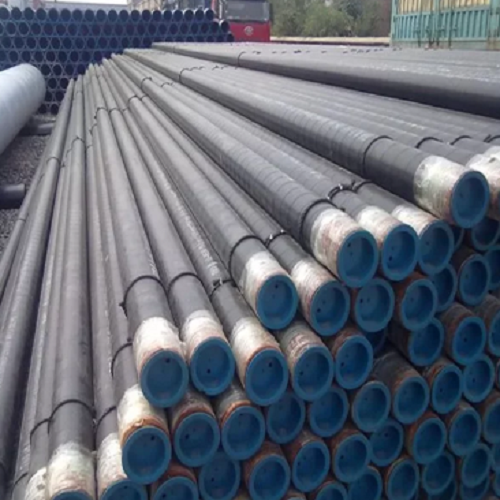

TPEP anti-corrosion steel pipe is a corrosion-resistant pipe coated with two-component atmospheric pressure hardening paint. Its excellent corrosion resistance makes it ideal for use in a variety of applications, including drainage and water supply. The pipe has excellent sealing performance and high bearing pressure, and its structure is simple and convenient.

The advantages of anti-corrosion steel pipe

TPEP anti-corrosion steel pipe has several advantages over other coating methods, including good adhesion to the steel surface, high productivity and excellent corrosion resistance. These properties make them useful in a variety of applications, including underground and subsea oil and gas transmission, chemical pipelines, and steel structures. The coating also provides improved electrical insulating properties.

TPEP anti-corrosion steel pipe can be widely used in water supply and drainage system. Its corrosion resistance and low water absorption make it a suitable material for buried pipelines. The material is used in sewage treatment, water supply and drainage systems in buildings and industrial places.

TPEP anti-corrosion steel pipe has a long history of application in the water supply and drainage industry. It is a zinc-coated steel pipe to resist corrosion. It used to be the most popular type of pipe in water systems. However, this material is expensive to install and requires a lot of labor. While it is still used in smaller residential applications, it is rarely used in large commercial settings.

TPEP anti-corrosion steel pipe can withstand high temperature and high salt environment. Also suitable for chemical pipelines, thermal pipelines, steel structures, etc. It has high corrosion resistance, and its excellent corrosion resistance is reflected in its long service life.

The performance of anti-corrosion steel pipe

There are two main types of corrosion resistance of TPEP anti-corrosion steel pipes: intergranular corrosion and cavitation. Intergranular corrosion occurs due to the presence of contaminants in the pipeline. However, it can be minimized with proper how-to guides. For internal oil and gas piping, epoxy or polyurethane liners can prevent this corrosion process.

TPEP anti-corrosion steel pipe is an effective anti-corrosion solution for water pipes. It has excellent corrosion resistance, good electrical insulation and good mechanical strength. Compared with other similar products, its corrosion resistance is 3-5 times higher. It is also very economical. Suitable for water supply, drainage, oil and gas transportation, marine environment.

It is based on three-layer polyethylene (PE) technology. The pipes are made of three layers: one polyethylene coating, the second on the inside and the third on the outside. It has excellent corrosion resistance and low water absorption. Widely used in oil and gas pipelines, buried water pipes, fire sprinkler network.

Scope of application of anti-corrosion steel pipe

TPEP anti-corrosion steel pipe has been widely used in many fields. Widely used in coal mine underground water supply, underground water spray, positive and negative pressure ventilation, gas drainage, fire sprinkler network, etc. It is also used in industrial applications for the transport of corrosive media.

TPEP anti-corrosion steel pipe has the advantages of corrosion resistance, durability and flexibility. It can be used in a variety of applications including sewage treatment, water supply and piling. Whether the anti-corrosion steel pipe is on the ground or underground, it can easily adapt to the environment and better water supply and drainage.

If you want to buy this product, please don't hesitate to buy it with confidence, we will provide you with considerate service.