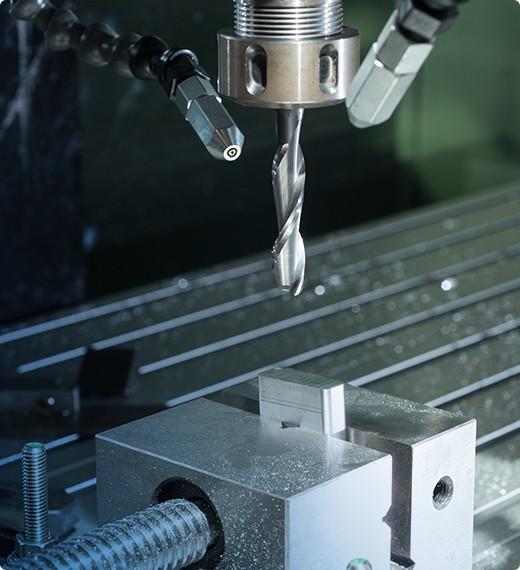

CNC machining is the process of making parts using computer-controlled machines.

The process of CNC machining can be used to create parts with a wide range of features, including complex shapes, intricate details and tight tolerances.

The advantages of CNC Machining

CNC machining is a manufacturing process in which computer-controlled machine tools are used to remove material from a workpiece to create a desired shape or finish. CNC machining is relatively quick and easy to set up, making it ideal for prototyping and small-scale production runs.

CNC machining has many advantages, including:

* Increased precision: CNC machining can produce parts that are more precise than those made by traditional machining methods.

* Improved repeatability: CNC machining can produce the same parts over and over again, ideal for mass production.

* Increased speed: CNC machines can work much faster than human operators, which means parts can be produced faster.

*Increased Versatility: CNC machining offers increased versatility to easily produce intricate parts.

The applications of CNC Machining

CNC machining is ideal for creating complex shapes and precise tolerances. Some of its most popular applications include automotive industry, medical implants and aerospace components. CNC machining can also be used to create prototypes and one-of-a-kind objects. Typical CNC parts include:

*Housings and Enclosures

*Brackets

*Manufacturing Fixtures

*Gears and Bearings

*Internal mechanical parts

*Medical equipment

About FRIMA

FRIMA Manufacturing is a precision CNC machining service provider with 12 years in the industry, offering CNC manufactured components. We are also a full-service shop offering milling, turning and assembly capabilities. With our certified CNC machining facilities, we serve companies in the medical, aerospace, defense, automotive, healthcare, electronics and other industries.For more information please email info@frimaparts.com.