Are you curious about how your air conditioning system keeps your home cool during hot summer days? One essential component that plays a significant role in the cooling process is the coaxial heat exchanger. But what exactly is it and how does it work? In this blog post, we'll delve into the ins and outs of coaxial heat exchangers, from their design to their advantages and disadvantages, as well as their various applications. So sit back, relax, and get ready to learn all about one of the unsung heroes of modern HVAC systems!

What is a coaxial heat exchanger?

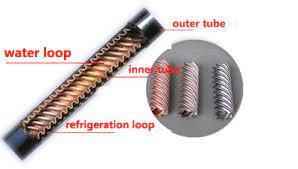

A coaxial heat exchanger is a type of heat transfer device that utilizes two concentric tubes to transfer thermal energy from one fluid to another. The inner tube serves as the conduit for the hot or cold fluid, while the outer tube acts as a shell through which a second fluid flows in order to absorb or release heat.In most cases, coaxial heat exchangers are used for air conditioning and refrigeration applications where high-efficiency cooling is required. They are typically made of copper, aluminum, or stainless steel due to their excellent thermal conductivity.One significant advantage of coaxial heat exchangers is their compact design - they take up less space than other types of heat exchangers with similar performance levels. Additionally, since there's no contact between fluids in different circuits (as opposed to traditional plate-type or shell-and-tube designs), cross-contamination risks are minimized.Coaxial heat exchangers represent an innovative solution for efficient and safe temperature control across numerous industries.

How does a coaxial heat exchanger work?

A coaxial heat exchanger operates using a concentric tube design, with one tube fitting inside the other. The two tubes are separated by an air gap or filled with insulation to prevent heat transfer between them. One fluid flows through the inner tube while another flows around it in the outer shell.Heat is transferred from the hot fluid flowing through the inner tube to the cooler fluid flowing around it. This occurs due to thermal conductivity, where atoms and molecules vibrate at different frequencies depending on their temperature. Heat energy transfers from higher frequency particles to lower frequency ones until both fluids reach equilibrium.The coaxial design allows for efficient heat transfer as there is a large surface area for contact between the two fluids, allowing for maximum heat exchange. Additionally, since there is no direct contact between the fluids, contamination or mixing of liquids can be avoided.A coaxial heat exchanger provides effective heating and cooling solutions across various industries such as HVAC systems in buildings or industrial processes that require precise temperature control.

Advantages of a coaxial heat exchanger

A coaxial heat exchanger has several advantages over other types of heat exchangers. One of the most significant benefits is its compact design, which allows for efficient use of space in a variety of applications.Another advantage is its ability to transfer heat quickly and effectively. The inner tube carries the hot fluid while the outer tube carries the cool fluid, allowing for maximum thermal efficiency.Coaxial heat exchangers are also easy to install and maintain due to their simple structure. They typically require minimal maintenance and can be easily cleaned without any special equipment or tools.Additionally, they are highly resistant to corrosion and erosion due to their durable materials such as stainless steel or titanium. This makes them ideal for use in harsh environments where other types of heat exchangers may fail.Coaxial heat exchangers offer versatility in terms of their application range, enabling them to be used in various industries such as food processing, chemical manufacturing, HVAC systems, renewable energy systems among others.A coaxial heat exchanger has many advantages that make it an attractive option for those seeking efficient and reliable thermal management solutions.

Disadvantages of a coaxial heat exchanger

While coaxial heat exchangers offer multiple advantages, they also have a few limitations that need to be considered before choosing this type of heat exchanger.Firstly, one of the main drawbacks is their limited capacity. Coaxial heat exchangers are often smaller than other types of heat exchangers and cannot handle large volumes of fluids. This makes them unsuitable for some industrial applications that require high flow rates or large volumes of fluids to be processed.Another disadvantage is their susceptibility to fouling. The design of a coaxial heat exchanger can make it difficult to clean and maintain, which increases the risk of fouling from dirt, debris, and other contaminants in the fluid being processed. This can lead to reduced efficiency over time if not cleaned regularly.Additionally, coaxial heat exchangers may not be suitable for extreme temperatures or pressures because they are typically made out of thinner materials compared to other types of heat exchangers. This means that they may not withstand harsh operating conditions without undergoing frequent maintenance or replacement.While coaxial heat exchangers are generally more affordable than other types due to their simple construction and lower material costs; however cheaper models might not always offer adequate performance when handling certain applications such as corrosive substances or viscous liquids.While there are several disadvantages associated with using a coaxial type Heat Exchange System - these do vary depending on what industry you're working in - weighing up its benefits against your specific requirements would determine whether a Coaxial Heat Exchanger will suit your needs better than any alternative solutions available on the market today.

Applications of a coaxial heat exchanger

The coaxial heat exchanger is a versatile device that can be used in various applications. One of the most common uses for this type of heat exchanger is in HVAC (heating, ventilation, and air conditioning) systems. It can efficiently transfer heat between two fluids without any risk of cross-contamination.Another application where coaxial heat exchangers are commonly used is in industrial processes such as food processing plants. These devices are ideal for heating or cooling liquids and gases during manufacturing processes. They are also widely used in the chemical industry where they play an important role in refining crude oil and other petrochemicals.Coaxial heat exchangers have found their way into renewable energy projects too, particularly geothermal energy systems. In these setups, the coaxial design allows for efficient transfer of thermal energy from underground to aboveground while maintaining high levels of efficiency.In addition, these types of heat exchangers are becoming increasingly popular for use in solar water heaters due to their ability to withstand high temperatures with minimal maintenance requirements.Whether it's heating or cooling fluids or transferring thermal energy across different media types, the coaxial heat exchanger has proven itself to be a reliable and cost-effective solution across multiple industries.

Conclusion

To sum up, a coaxial heat exchanger is an efficient and compact device used for transferring heat between two fluid streams. It works by utilizing the counterflow principle to maximize the temperature difference between the fluids while minimizing their mixing. By considering factors like flow rate, fluid properties, operating conditions, and budget constraints when selecting your equipment you can ensure that you get maximum performance from your system.Please contact us,if you need.zy@jsyuanzhuo.com