Snap dome looks like a small snap dome, and it needs to go through many processes in production to complete. Friends who know snap dome should have heard that snap dome has longevity and strength, and can use different kinds of materials, such as stainless steel sus301 material and stainless steel sus304 material. We're curious if the material of the dome is the same. Why is power not the same as life? This is related to the production process of dome. Next, let's take a look at the production process of the metal dome.

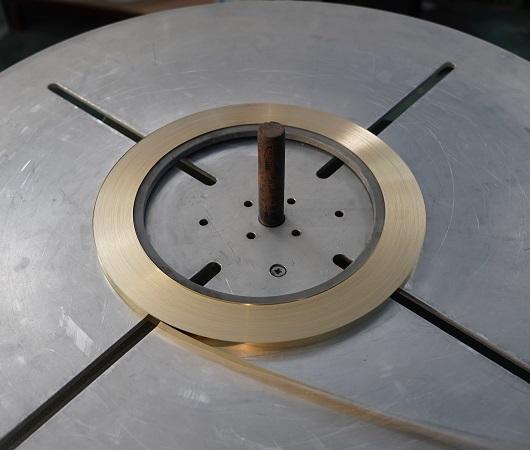

Before production, it must first be produced according to the materials required by the merchant. This step is often called material selection. Generally speaking, 301 material can meet the needs of most customers. Customers with special needs can use 304 material or nickel-plated, gold, silver and other processing to meet the actual needs of customers. After confirming the material, equally important is the stamping step. This step is important to efficiently determine strength and avoid secondary adjustments. Therefore, the strength must be determined before use, so as not to cause unnecessary trouble in the process.

After stamping is basically formed. It is necessary to carry out surface treatment on the stamped dome. There are many burrs on the dome to avoid workers being injured by burrs during the assembly process, and the gloss and friction of the dome should also be appropriately increased. Therefore, the surface treatment of snap dome will be carried out according to the needs of customers, so as to facilitate the normal use of pots required by customers. Snap dome is easily damaged during use, so the metal dome will be randomly checked during the production process to ensure the quality of the metal dome. It can be used better and longer without breaking away from the original position during use.

Of course, the snap dome has been made, but the newly produced snap dome cannot be used directly with the product. We also need to clean them before shipment. The purpose of cleaning is to prevent the finished product from being wasted during assembly. However, QA is a very important step. In the production of tens of thousands of snap domes, if the random inspection is not carried out in time, it may cause problems in the whole batch of goods. This kind of problem cannot be said to be a defective product, it may be that the strength or lifespan is not the same as that of the orderer. If these parameters are not consistent, it will cause a certain loss to the manufacturing, because the snap dome is a special customized product, which is different from other products. Therefore, the step of quality inspection is an important step for every dome manufacturer.