The installation of the refrigerator external condenser is mostly installed directly against the back wall. This actually has a big disadvantage: the heat of the condenser tube is undoubtedly transferred to the iron sheet, and the inner side of the iron sheet is close to the insulation layer, so the heat can only be transferred outward. Although part of the heat of the iron sheet is transferred to the space (atmosphere), a large part of the heat is transferred back to the condensation pipe due to the closeness of the condensation pipe, so that it is transferred repeatedly. First, the condensation time is increased and the condensation speed is reduced. The second is to waste the already tense condensation area, reduce the condensation effect, make the condensation temperature drop slowly, the condensation pressure is higher than normal, the refrigeration efficiency is low, and the power consumption increases.

Even the filter and capillary are hot, even hot, which overheats the temperature of the refrigerant and reduces the cooling effect. Therefore, the installation should be properly separated from the box wall by about 3~5 cm, so that it can be fully ventilated and dissipated to ensure the condensation effect, which should be paid attention to when replacing the condenser!

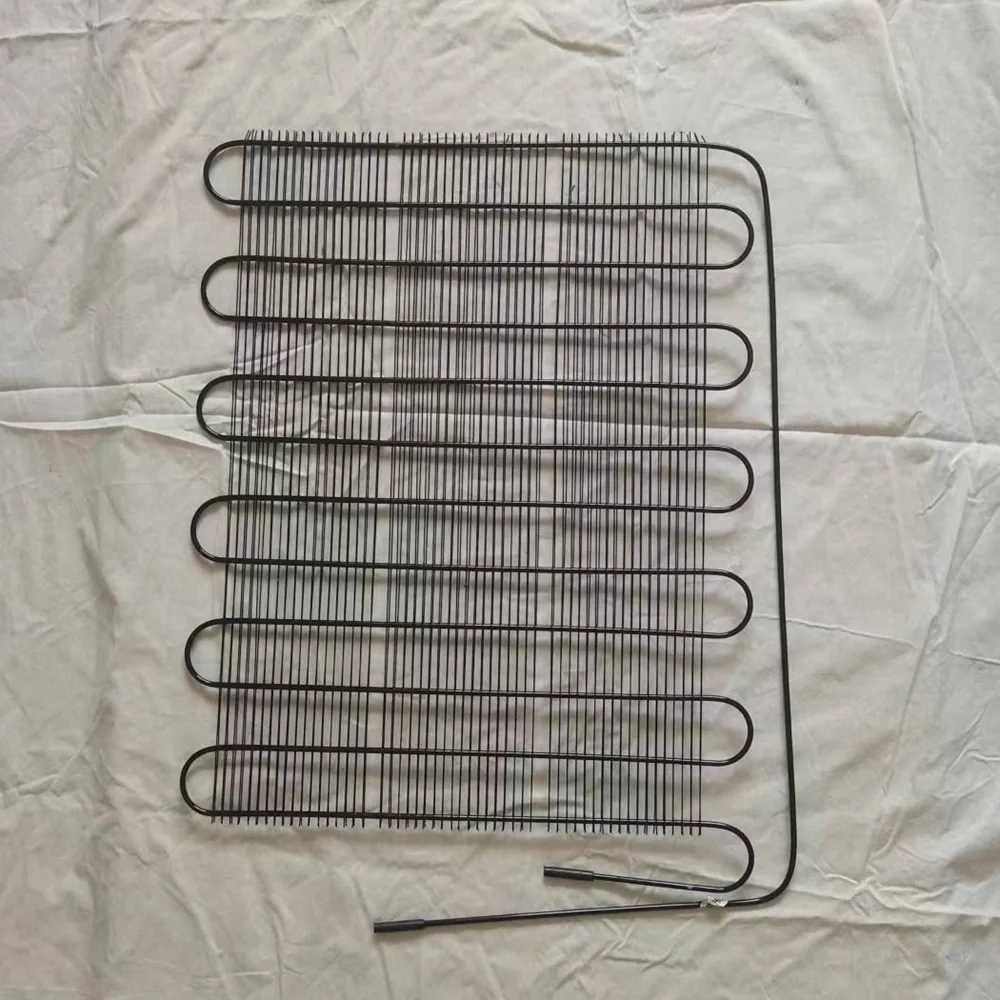

The condensing pipe of the original refrigerator is installed inside, and the condensing pipe is close to the iron sheet of the refrigerator, and the heat is transmitted outwards by the iron sheet. The iron sheet is like the fin of the finned condenser, and the heat is transferred to the outside space; it is also connected with the steel wire on the condenser. Like louvers, steel wire or louvers are used to increase the heat transfer area.

Similarly, the inner tank aluminum skin of the refrigerator freezer, the evaporation tube is also close to the aluminum skin, relying on the aluminum skin to transfer heat (cooling capacity) to the box.

Absolutely none of the exposed condensers of the original old-fashioned refrigerators were installed close to the back wall, which explains this reason.

This is the principle theory of heat transfer.

The condensers currently available on the market have small tube diameters and thin tubes. For a large-capacity refrigerator, the condensing area of one piece is still small, so two smaller ones must be connected in series to ensure a sufficient condensing area. During installation, it is also required that the two pieces and the box wall should be separated from each other. Although the operation is more troublesome, it absolutely avoids worries.

Refrigerator External Condenser Manufacturer - Bodu Refrigeration Equipment

Dongtai Bodu Refrigeration Equipment Co., Ltd. mainly engaged in the research and development and production of refrigerators, freezers, water dispensers, shutter-type condensers, wire tube condensers products.

The company has been committed to the innovation and development of new technologies in the dry refrigeration industry, adhered to the road of technological innovation, and used the new design of wire tube condensers to replace high-cost copper tube condensers.

If you want to wholesale wire tube refrigerator condenser, please contact us for more information.