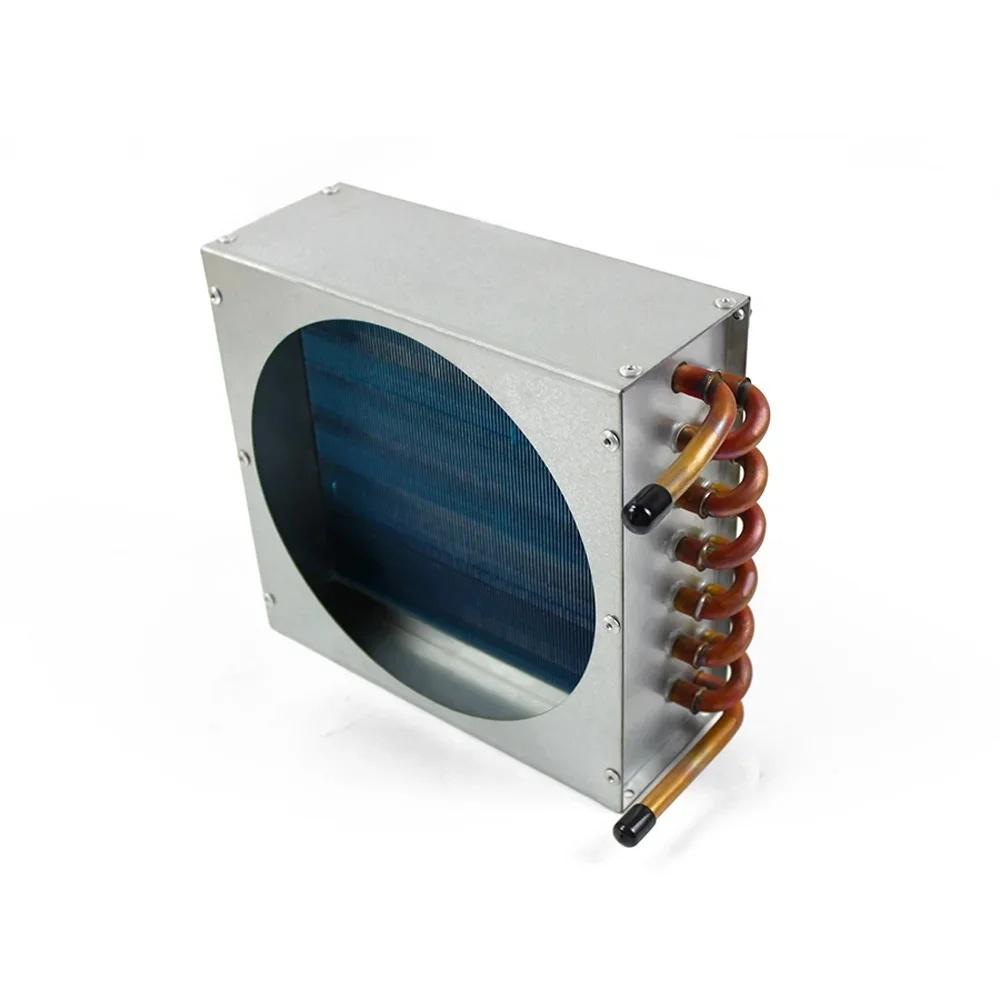

Air cooled condenser is a common heat exchange equipment, widely used in air conditioning, refrigeration, refrigeration, and other fields. It cools down the heat medium by transferring the heat in the heat medium to the surrounding air. In the design and manufacture process of air cooled condenser, material selection and manufacturing process are very important links, which directly affect the performance and service life of the condenser.

First of all, material selection is the key to air cooled condenser design. Common air cooled condenser materials include copper, aluminum, stainless steel, etc. Copper has good thermal conductivity and corrosion resistance, conducts heat efficiently, and is less susceptible to corrosion. Aluminum has a low density and good thermal conductivity, which can improve the heat transfer efficiency of the condenser. Stainless steel has excellent corrosion resistance and mechanical properties and is suitable for use in some special environments.

When selecting materials, the working conditions and use environment of the condenser need to be considered. If the condenser needs to work in a humid environment, stainless steel may be a better choice because it resists corrosion in wet environments. If the condenser needs to work in a high-temperature environment, copper may be a better choice because of its high-temperature resistance. In addition, the cost and processability of materials need to be considered to ensure the manufacturing cost and process feasibility of the condenser.

Secondly, the manufacturing process also has an important impact on the performance and service life of the air-cooled condenser. Common manufacturing processes include welding, riveting, and gluing, among others. Welding is a commonly used connection method, which can achieve a firm connection of materials, but thermal stress will be generated during the welding process, which may lead to material deformation and cracks. Riveting, a method of joining materials together with rivets, reduces thermal stress, but the connection may be weaker than welding. Gluing is a method of bonding materials together with glue, which can achieve seamless connection, but the high-temperature resistance and corrosion resistance of the glue needs to be guaranteed.

In the manufacturing process, the structural design and manufacturing accuracy of the condenser also need to be considered. The structural design of the condenser should be reasonable to ensure the cooling effect and heat transfer efficiency. The manufacturing precision should be high to ensure the tightness and stability of the condenser. In addition, it is also necessary to pay attention to the cleaning and protective measures during the manufacturing process to prevent impurities and corrosion from affecting the condenser.

In short, the material selection and manufacturing process of the air cooled condenser is an important part of the design and manufacture of the condenser. A reasonable selection of materials and manufacturing processes can improve the performance and service life of the condenser and ensure its stable operation under various working conditions. In future development, with the continuous advancement of material science and manufacturing technology, the material selection and manufacturing process of air cooled condensers will be more diversified and refined, providing more possibilities for performance improvement and application expansion of the condenser.

Cause analysis and treatment method of air-cooled condenser failure

What are the factors that affect the service life of air-cooled condenser

What are the energy-saving and environmental protection features of air-cooled condensers?

Factors affecting the service life of air-cooled condensers and how to prolong their life

https://www.ningbo-senjun.com/Material-selection-and-manufacturing-process-of-air-cooled-condenser.html