Introduction:

In today's fast-paced industrial landscape, precision and efficiency are paramount. One technology that has revolutionized the manufacturing industry is the Computer Numerical Control (CNC) lathe machine. This advanced piece of machinery has transformed traditional lathe operations, enabling manufacturers to achieve unprecedented levels of accuracy, productivity, and versatility. In this article, we will explore the capabilities, advantages, and applications of the cnc lathe machine, highlighting its pivotal role in modern manufacturing.

Understanding the CNC Lathe Machine:

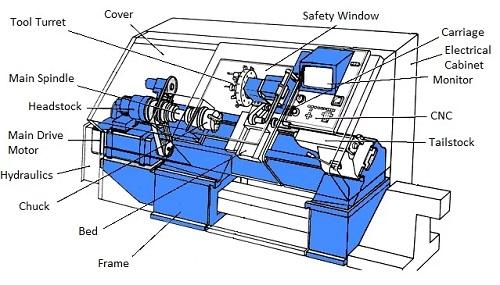

The CNC lathe machine is a computer-controlled device that automates the process of turning raw materials such as metal or wood into complex components with high precision. By using pre-programmed instructions, CNC lathes can perform a wide range of operations, including cutting, drilling, facing, threading, and tapering. These machines utilize various tools, such as drills, cutting tools, and grinders, to shape and refine the workpiece to the desired specifications.

Unparalleled Precision and Accuracy:

One of the standout features of the CNC lathe machine is its ability to achieve unparalleled precision and accuracy. By eliminating human error, these machines consistently produce components with tight tolerances, resulting in higher quality finished products. The precise movements of the CNC lathe, controlled by the computer, ensure that each cut and operation is executed with utmost accuracy, leading to improved consistency and reduced scrap rates.

Enhanced Productivity and Efficiency:

In addition to precision, CNC lathes significantly enhance productivity and efficiency in manufacturing processes. These machines can operate 24/7 without the need for constant human supervision, allowing for uninterrupted production cycles. CNC lathes also excel in rapid tool changes and quick setup times, minimizing downtime and maximizing output. With their high-speed capabilities, these machines can complete complex tasks in a fraction of the time it would take with traditional manual lathes.

Versatility and Flexibility:

CNC lathes offer unparalleled versatility and flexibility, making them suitable for a wide range of industries and applications. With the ability to work on various materials, including metals, plastics, and composites, CNC lathes can accommodate diverse manufacturing needs. Additionally, these machines can produce intricate and complex shapes, enabling manufacturers to create customized components that meet specific requirements.

Applications Across Industries:

The CNC lathe machine finds extensive use in numerous industries. In automotive manufacturing, it plays a vital role in producing engine components, transmission parts, and chassis components. Aerospace and defense industries rely on CNC lathes to fabricate precision parts for aircraft and spacecraft. The medical sector utilizes these machines for manufacturing implants, prosthetics, and surgical instruments. Furthermore, the electronics industry benefits from CNC lathes for creating connectors, terminals, and other intricate parts.

Conclusion:

The CNC lathe machine has ushered in a new era of precision, productivity, and flexibility in the manufacturing industry. With their unparalleled accuracy, efficiency, and versatility, these computer-controlled machines have become indispensable in various sectors. As technology continues to advance, we can expect further enhancements and innovations in CNC lathe machines, paving the way for even more sophisticated manufacturing processes. In this era of precision engineering, the CNC lathe machine stands as a symbol of progress, redefining the boundaries of what is achievable in modern manufacturing.