Welcome to our blog post on the cutting-edge BPH Model ZL52A! Are you curious about how this groundbreaking technology can revolutionize your heat exchange systems? Look no further, as we dive deep into the world of brazed plate heat exchangers and uncover all there is to know about this marvel of engineering. Whether you're an industry expert or simply interested in exploring innovative solutions, join us as we take a comprehensive journey through the features, benefits, and applications of the BPH Model ZL52A. Get ready to have your mind blown by its efficiency, versatility, and unrivaled performance – let's get started!

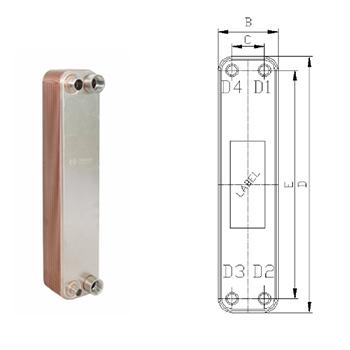

Overview of the BPH Model ZL52A

https://www.yojointernational.com/Brazed-Plate-Heat-Exchanger/Brazed-Plate-Heat-Exchanger-ZL52A.shtml that has been designed to be used in a wide variety of applications. It is available in a variety of sizes and configurations to meet the needs of different customers. The BPH Model ZLA is made from stainless steel and features a number of benefits that make it an ideal choice for many different types of systems.

Key Features of the BPH Model ZL52A

The BPH Model ZL52A is a brazed plate heat exchanger that is designed for use in a wide variety of industries. Some of the key features of this model include:

-A maximum operating pressure of 150 psi

-A maximum operating temperature of 350 degrees Fahrenheit

-An efficiency rating of 95 percent or higher

-A wide variety of sizes and configurations to choose from

-The ability to handle both liquids and gases

-A robust construction that can withstand harsh conditions

-Low maintenance requirements

Benefits of the BPH Model ZL52A

The Brazed Plate Heat Exchanger (BPHE) is a highly efficient and compact heat exchanger that is widely used in a variety of industries. The BPH model ZL52A is a state-of-the-art BPHE that offers many benefits over other types of heat exchangers. Some of the key benefits of the BPH model ZL52A include:

1. Increased Efficiency: The BPH model ZL52A features a unique plate design that allows for increased heat transfer efficiency. This results in less energy being required to operate the heat exchanger, which can lead to significant cost savings over time.

2. Compact Design: The BPH model ZL52A is significantly smaller than other types of heat exchangers, making it ideal for use in space-restricted areas. This also makes the unit easier to transport and install.

3. Durability: The BPH model ZL52A is built with high-quality materials that make it extremely durable and long-lasting. This ensures that the unit will provide years of reliable operation.

4. Easy Maintenance: The BPH model ZL52A is designed for easy maintenance and can be cleaned quickly and easily if needed. This minimizes downtime and keeps operating costs low.

Applications for the BPH Model ZL52A

The BPH Model ZL52A is a Brazed Plate Heat Exchanger that can be used in a variety of applications, such as:

- Air Conditioning and Refrigeration

- Automotive and Transportation

- Chemical Processing

- Food and Beverage Processing

- HVAC and R

- Oil and Gas Processing

- Power Generation

- Pulp and Paper Processing

- Waste Heat Recovery Systems

Advantages and Disadvantages of the BPH Model ZL52A

The BPH model ZLA heat exchanger is a brazed plate type heat exchanger that is widely used in many industries. Its main advantages are its high thermal efficiency and its ability to handle corrosive fluids. Its disadvantages include its high cost and the need for regular maintenance.

Advantages:

1. High thermal efficiency: The BPH model ZLA heat exchanger is designed to maximize heat transfer efficiency and reduce operating costs. It uses a brazed plate structure, which eliminates the need for gaskets and reduces the risk of leakage.

2. Corrosion resistance: The BPH model ZLA heat exchanger is designed to resist corrosion from various fluids, including hot water, steam, refrigerants, and oil. This makes it ideal for industrial applications that require high levels of corrosion resistance.

3. Compact design: The BPH model ZLA heat exchanger is very compact in size and can be easily installed in tight spaces. This makes it ideal for small-scale applications where space is limited.

Disadvantages:

1. High cost: Due to its advanced design and materials used, the BPH model ZLA heat exchanger is relatively expensive compared to other types of heat exchangers on the market.

2. Maintenance requirements: The BPH model ZLA heat exchanger requires regular maintenance in order to maintain its optimal performance. This includes checking for leaks, inspecting seals, and cleaning the plates periodically.

Installation Process for the BPH Model ZL52A

The installation process for the BPH Model ZL52A is a simple and straightforward process that can be completed in just a few minutes. First, the heat exchanger must be properly positioned on the installation site. Second, the mounting brackets must be securely attached to the heat exchanger. Third, the piping must be properly connected to the heat exchanger. The unit must be filled with the proper coolant and pressurized according to manufacturer's specifications.

Maintenance Tips for Proper Operation

The brazed plate heat exchanger (BPHE) is a compact and efficient heat exchanger that is widely used in a variety of industries. As with any piece of equipment, proper maintenance is essential to ensure optimal performance and longevity.

Here are some tips for maintaining your BPHE:

- Keep the unit clean: Periodically clean the unit to remove any dirt or debris that may have accumulated. This will help keep the unit operating efficiently and prevent potential problems.

- Inspect the plates: Inspect the plates for any signs of damage or wear. If you notice any damage, replace the plates as soon as possible.

- Check the seals: Make sure that all seals are intact and in good condition. If you notice any leaks, repair or replace the seals as soon as possible.

- Test the unit regularly: Regularly test the unit to ensure that it is operating properly. This will help you identify any potential problems so that they can be fixed before they cause major issues.

Conclusion

The BPH Model ZL52A is a powerful and efficient Brazed Plate Heat Exchanger that can improve the performance of any application. It offers superior thermal efficiency, low pressure drops, and fast heat transfer to help you get the most out of your system. With its wide range of applications, this model makes it easy to find a solution for most needs. Whether you’re looking for an industrial grade or commercial grade heat exchanger, the BPH Model ZL52A will be able to provide reliable and effective solutions.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and production.Welcome to inquiry if you need to know more about BPH Model ZL52A details or order wholesale.