Are you tired of dealing with inefficient heat transfer systems? Do you want to explore a better alternative that guarantees optimal performance and energy savings? Look no further! In this blog post, we will take you on an exciting journey through the world of coaxial heat exchangers. Whether you are a homeowner or an industry professional, we have got all your questions covered. Get ready to uncover the pros and cons of different types of coaxial heat exchangers and revolutionize the way you think about managing thermal energy. Let's dive in!

Introduction to Coaxial Heat Exchangers

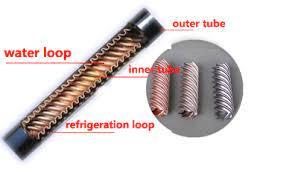

Coaxial heat exchangers are a type of heat exchanger in which two fluids flow through separate, concentric tubes. The inner tube is surrounded by an outer tube, and the two fluids flow in opposite directions. Heat is transferred from one fluid to the other through the walls of the tubes.

Coaxial heat exchangers are often used when one of the fluids is a gas and the other is a liquid. They are also used when both fluids are liquids, but the difference in their boiling points is large enough that there is a risk of one fluid vaporizing into the other. https://www.yojointernational.com/pro_b/ are also sometimes used in applications where one of the fluids is corrosive and/or toxic.

There are several advantages to using a coaxial heat exchanger. One advantage is that they are very compact, which makes them well suited for applications where space is limited. Another advantage is that they can achieve very high rates of heat transfer due to the large surface area between the two fluids. Additionally, coaxial heat exchangers can be designed so that one or both fluid streams can be recirculated, which allows for better control over the temperature difference between the two fluids.

There are also some disadvantages to using coaxial heat exchangers. One disadvantage is that they can be more expensive than other types of heat exchangers due to their complex design. Additionally, they can be more difficult to clean and maintain than other types of heat exchangers because of their complex design.

Types of Coaxial Heat Exchangers

Coaxial heat exchangers are one of the most popular types of heat exchangers used in a variety of industries. There are several different types of coaxial heat exchangers, each with its own set of pros and cons. Here is a closer look at some of the most common types of coaxial heat exchangers:

Plate-and-Frame Heat Exchangers: Plate-and-frame heat exchangers are one of the most efficient types of coaxial heat exchangers. They consist of a series of metal plates that are separated by gaskets. The plates are then sandwiched together and clamped together to form a tight seal. This type of heat exchanger is often used in applications where two fluids need to be heated or cooled at different rates.

Shell-and-Tube Heat Exchangers: Shell-and-tube heat exchangers are another popular type of coaxial heat exchanger. They consist of a series of tubes that are placed inside a larger shell. The shell is then filled with a fluid, such as water, which transfers the heat from the tubes to the fluid. This type of heat exchanger is often used in applications where one fluid needs to be heated or cooled more than the other.

Air-Cooled Heat Exchangers: Air-cooled heat exchangers are just what they sound like – they use air to cool the fluids that pass through them. This type ofheat exchanger is often used in applications where the fluids need to be cooled quickly and efficiently.

These are just a few of the most common types of coaxial heat exchangers. Depending on your needs, there may be other types that are better suited for your application. Be sure to speak with an experienced heat exchanger specialist to determine which type is right for you.

Pros and Cons of Each Type

There are three main types of coaxial heat exchangers: plate, tube-in-tube, and shell-and-tube. Each has its own set of pros and cons that should be considered when choosing the right type of heat exchanger for your needs.

Plate Heat Exchangers:

Pros:

-Can handle higher temperatures and pressures than tube-in-tube or shell-and-tube exchangers

-More efficient than tube-in-tube exchangers

-Less expensive than shell-and-tube exchangers

Cons:

– Can become fouled more easily than tube-in-tube or shell-and-tube exchangers

– Not as rugged as shell-and=tube exchangers

Tube-In Tube Heat Exchangers:

Pros:

– More resistant to fouling than plate exchangers

– More rugged than plate exchangers

– Cheaper than shell and tube exchangers

Cons:

– Less efficient than plate exchangers

Shell and Tube Heat Exchanger:

Pros:

– Most resistant to fouling out of the three types

– Can handle the highest temperatures and pressures out of the three types

– Most rugged out of the three types

Applications and Uses for Each Type

There are many different types of coaxial heat exchangers that have been designed for specific applications. Below is a brief description of each type along with its advantages and disadvantages:

-Shell and tube heat exchangers are the most common type of heat exchanger used in industry. They are suitable for a wide range of applications, including those involving high pressures and temperatures. Shell and tube heat exchangers have a simple design and are easy to construct and maintain. However, they are not as efficient as some other types of heat exchangers and can be more expensive to purchase.

-Plate and frame heat exchangers consist of a series of metal plates that are sandwiched together with gaskets in between. These types of heat exchangers are very efficient and can handle higher pressures than shell and tube heat exchangers. They are also relatively easy to construct and maintain. However, plate and frame heat exchangers can be more expensive than shell and tube heat exchangers.

Coaxial heat exchangers are composed of two concentric tubes through which the two fluids to be exchanged flow in opposite directions. Coaxial heat exchangers have a very compact design which makes them ideal for applications where space is limited. They are also very efficient, although they can be more expensive than shell and tube or plate and frame heat exchangers.

Factors to Consider When Choosing Between Types

When choosing between types of coaxial heat exchangers, there are several factors to consider, including:

-The type of fluid being heated or cooled

-The desired flow rate

-The required heat transfer rate

-The operating pressure and temperature

Additionally, it is important to consider the space constraints of the application and the maintenance requirements of the chosen heat exchanger.

Maintenance Requirements for Each Type

https://www.yojointernational.com/news/Working-Principle-of-Coaxial-Heat-Exchangers.shtmlare a type of heat exchanger that uses a central shaft to surround and transfer heat between two fluids. There are three main types of coaxial heat exchangers: single-tube, double-tube, and shell-and-tube. Each type has its own advantages and disadvantages, as well as different maintenance requirements.

Single-Tube Heat Exchangers: Single-tube heat exchangers are the simplest and most common type of coaxial heat exchanger. They consist of a single tube surrounded by another fluid. Single-tube heat exchangers are typically used for low-temperature applications and can be made from a variety of materials, including stainless steel, copper, and aluminum.

Maintenance Requirements: Single-tube heat exchangers require very little maintenance. The only thing you need to do is periodically check the tube for any damage or corrosion.

Double-Tube Heat Exchangers: Double-tube heat exchangers are more complex than single-tube heat exchangers and consist of two tubes surrounded by another fluid. Double-tube heat exchangers are typically used for high-temperature applications and can also be made from a variety of materials, including stainless steel, copper, and aluminum.

Maintenance Requirements: Double-tube heat exchangers require more maintenance than single-tube heat exchangers. You need to periodically check both tubes for any damage or corrosion. You also need to make sure that the tubes are properly insulated to prevent heat losses. Finally, you need to make sure that the seals between the two tubes are tight and free of leaks.

Shell-and-Tube Heat Exchangers: Shell-and-tube heat exchangers are the most complex type of coaxial heat exchanger and consist of a shell containing multiple tubes surrounded by another fluid. Shell-and-tube heat exchangers are typically used for high-temperature applications and can also be made from a variety of materials, including stainless steel, copper, and aluminum.

Maintenance Requirements: Shell-and-tube heat exchangers require more maintenance than the other types of coaxial heat exchangers. You need to periodically check all of the tubes for any damage or corrosion. You also need to inspect the seals between each tube and make sure they are tight and free of leaks. Additionally, you need to inspect the shell for any cracks or wear and tear that could lead to a leak.

Conclusion

This article has explored the different types of coaxial heat exchangers and their pros and cons. Each type of coaxial heat exchanger is suitable for different applications, so it’s important to consider your specific needs before making a purchase. We hope that this article helps you make an informed decision about which type of coaxial heat exchanger is right for you.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.Welcome to inquiry if you need to know more about Coaxial heat exchangers details or order wholesale.zy@jsyuanzhuo.com