Welcome to our blog, where we delve into the fascinating world of extruded aluminum profiles! These versatile and durable components play a crucial role in various industries and applications. Whether you're involved in construction, automotive manufacturing, or even DIY projects, understanding the different types of extruded aluminum profiles is essential for selecting the right one for your specific needs.

In this article, we will explore the common types of extruded aluminum profiles, their respective applications, as well as their advantages and disadvantages.

Common Types of Extruded Aluminum Profiles

When it comes to https://www.bsaluminum.com/Extruded-Aluminum-Profiless, there are several common types that are widely used in various industries. Each type of profile has its own unique characteristics and features, making them suitable for different applications.

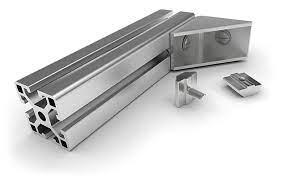

One common type is the T-slot profile, which is named after its shape resembling the letter "T". These profiles have slots on one or more sides, allowing for easy attachment of accessories such as connectors and brackets. T-slot profiles are commonly used in applications like framing systems, machine guarding, and conveyor systems.

Another popular type is the round tube profile. As the name suggests, these profiles have a circular cross-section. Round tube profiles offer excellent strength-to-weight ratio and are often used in structures where lightweight yet durable materials are required. They find applications in areas such as automotive manufacturing, furniture construction, and architectural designs.

Rectangular bar profiles are another common choice for many projects. These profiles have a flat surface on one side and varying dimensions on the other sides. They provide high structural integrity and can be easily connected with other components using fasteners or welding. Rectangular bar profiles find uses in industries ranging from aerospace to marine construction.

The L-shaped angle profile is yet another versatile option available for extruded aluminum users. With their 90-degree angle shape, they provide stability and support when two surfaces meet at a corner joint. Angle profiles can be found in applications like shelving units, framework supports, and decorative trims.

We have the U-channel profile – a U-shaped channel with equal-length legs forming an open top design. This type of profile offers excellent rigidity while providing options for hiding cables or wires within the channel itself.

These descriptions only scratch the surface of what each type of extruded aluminum profile has to offer! By understanding their advantages and limitations better suited for your specific project requirements!

Applications of Each Profile Type

Extruded aluminum profiles are versatile and can be used in a wide range of applications across various industries. Let's explore the different profile types and their specific uses.

1. T-Slot Profiles: These profiles have a T-shaped slot that allows for easy assembly, making them ideal for constructing frameworks, workbenches, machine guards, and automation systems. They are commonly used in manufacturing facilities, workshops, and industrial settings.

2. Square Profiles: With their uniform shape and straight edges, square profiles are often utilized in architectural projects such as window frames, door frames, curtain walls, and decorative trims. They also find application in furniture construction where clean lines are desired.

3. Round Profiles: The smooth curves of round profiles make them suitable for applications requiring aesthetics or rounded edges like handrails, lighting fixtures, display stands or signage poles.

4. Custom Profiles: Custom extruded aluminum profiles allow for flexibility in design and can be tailored to suit unique project requirements. They find use in specialized sectors such as automotive engineering (for chassis components), aerospace industry (for structural parts), or renewable energy sector (for solar panel frames).

Advantages and Disadvantages of Extruded Aluminum Profiles

One major advantage of extruded aluminum profiles is their versatility. These profiles can be customized to meet the specific requirements and designs of various projects, making them suitable for a wide range of applications in industries like construction, automotive, electronics, and more.

Another key advantage is the lightweight nature of extruded aluminum profiles. Compared to other materials such as steel or wood, aluminum offers a high strength-to-weight ratio while still being easy to handle and transport. This makes it an ideal choice for applications where weight reduction is crucial.

Extruded aluminum profiles are also highly durable and resistant to corrosion. Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent rusting or deterioration over time. This durability ensures that these profiles have a long lifespan with minimal maintenance required.

Additionally, extruded aluminum profiles offer excellent thermal conductivity. They efficiently dissipate heat away from components or structures, making them suitable for use in heat sinks or cooling systems.

Disadvantages of Extruded Aluminum Profiles

However, there are some drawbacks associated with using extruded aluminum profiles as well. One disadvantage is that they can be more expensive compared to other materials such as plastic or wood.

Furthermore, although they are durable against corrosion, exposure to certain chemicals or harsh environments may cause damage over time if not properly protected or coated.

Moreover, while extrusion allows for complex shapes and designs, there are limitations on the size and thickness that can be achieved through this process. For larger structures requiring heavy-duty support beams or thick panels, alternative materials might be more suitable.

While extruded aluminum profiles offer numerous advantages such as versatility and durability along with excellent thermal properties; it's important to consider factors like cost and environmental conditions before choosing them for your project. By carefully evaluating these pros and cons alongside your specific needs will help you make an informed decision about whether extruded aluminum profiles are the right choice for you.

Factors to Consider When Choosing the Right Profile for Your Project

When it comes to selecting the right extruded aluminum profile for your project, there are several important factors to consider. First and foremost, you need to evaluate the specific requirements of your project. What is the purpose of the structure? Will it be exposed to extreme weather conditions or corrosive environments?

Another crucial factor is aesthetics. Do you want a sleek and modern look or a more traditional design? The choice of profile shape and finish will play a significant role in achieving the desired aesthetic appeal.

Durability is also key when choosing an extruded aluminum profile. Consider factors such as strength, resistance to wear and tear, and longevity. Aluminum profiles offer excellent durability compared to other materials but different profiles have varying degrees of strength.

Cost is another vital consideration. Extruded aluminum profiles can vary significantly in price depending on their complexity and size. It's essential to balance budget constraints with quality requirements.

Conclusion

Extruded aluminum profiles offer numerous advantages like versatility in design possibilities, lightweight yet durable construction materials, recyclability contributing to sustainability efforts,and high strength-to-weight ratio.

Wuxi Belson Aluminum Tube Co.,Ltd focused on the development and production of pneumatic parts, especially aluminum cylinder barrels,and a professional Extruded aluminum profiles manufacturer.Welcome to inquiry if you need to know more about Extruded aluminum profiles details or order wholesale.

Email:info@bsaluminum.com.