Brazed plate heat exchangers are widely used in various industries for their high heat transfer efficiency and compact design. However, like any other heat exchanger, they can experience issues such as blockage and scaling, which can affect their performance and efficiency. In this article, we will discuss how to confirm blockage and scaling of a brazed plate heat exchanger and the steps to take to address these problems effectively.

Understanding Blockage and Scaling

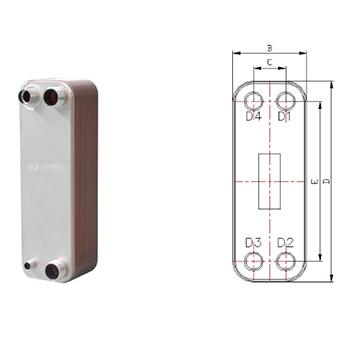

Blockage and scaling are common problems that can occur in a https://www.yojointernational.com/Brazed-Plate-Heat-Exchanger/Brazed-Plate-Heat-Exchanger-ZL95A.shtml. Blockage refers to the accumulation of debris, dirt, or other solid particles in the channels of the heat exchanger, restricting or blocking the flow of the fluid. Scaling, on the other hand, refers to the deposition of mineral deposits, such as calcium or magnesium, on the surface of the heat exchanger plates. Both blockage and scaling can reduce heat transfer efficiency and increase pressure drop, leading to decreased performance and potential equipment failure.

Confirming Blockage and Scaling

Reduced Heat Transfer Efficiency:

One of the first signs of blockage or scaling in a brazed plate heat exchanger is a noticeable decrease in heat transfer efficiency. If you observe that the heat exchanger is not effectively transferring heat between the two fluids, it may indicate the presence of blockage or scaling.

Increased Pressure Drop:

Blockage and scaling can also cause an increase in pressure drop across the heat exchanger. If you notice a significant rise in pressure on either the hot or cold side of the heat exchanger, it could be an indication of blockage or scaling.

Flow Rate Irregularities:

Another way to confirm blockage or scaling is by observing flow rate irregularities. If you notice a decrease in flow rate on either the hot or cold side, it may suggest that the channels within the heat exchanger are partially or completely blocked.

Visual Inspection:

Performing a visual inspection of the heat exchanger can also help in confirming blockage or scaling. Look for any visible signs of debris, dirt, or mineral deposits on the surface of the plates or within the channels. If you see any accumulation, it is a clear indication of blockage or scaling.

Steps to Address Blockage and Scaling

Chemical Cleaning:

Chemical cleaning is an effective method to remove blockage and scaling from a brazed plate heat exchanger. Use a suitable cleaning solution that can dissolve or loosen the deposits. Follow the manufacturer's instructions and ensure proper safety precautions while handling the cleaning chemicals.

Mechanical Cleaning:

In some cases, mechanical cleaning may be required to remove stubborn blockages or scaling. Use a soft brush or sponge to gently scrub the surface of the plates and remove any accumulated debris or mineral deposits. Be careful not to damage the plates or the brazed joints.

Regular Maintenance:

Prevention is always better than cure. Implementing a regular maintenance schedule for your brazed plate heat exchanger can help prevent blockage and scaling issues. Regularly inspect the heat exchanger, clean it if necessary, and ensure proper water treatment to minimize scaling.

Water Treatment:

Water quality plays a crucial role in preventing scaling in a brazed plate heat exchanger. Implement a suitable water treatment system to minimize the mineral content in the water. This can help reduce the chances of scaling and prolong the lifespan of the heat exchanger.

Conclusion

Confirming blockage and scaling in a brazed plate heat exchanger is essential for maintaining its performance and efficiency. By understanding the signs and symptoms of blockage and scaling, you can take the necessary steps to address these issues effectively. Regular maintenance, proper cleaning, and water treatment are crucial in preventing and managing blockage and scaling problems. By implementing these measures, you can ensure the optimal performance and longevity of your brazed plate heat exchanger.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.Welcome to contact us if you need to know more about brazed heat exchanger details or order wholesale.

Email:zy@jsyuanzhuo.com

Related News:What Are The Applications Of Brazed Heat Exchangers In The Paper Industry?