In the realm of modern manufacturing, CNC (Computer Numerical Control) machining manufacturers emerge as the stalwarts of precision engineering. From aerospace to automotive, medical to electronics, these adept craftsmen play a pivotal role in shaping industries worldwide. This article delves into the intricate world of CNC machining manufacturer, exploring their unparalleled expertise, innovative approaches, and the impact they wield in today's industrial landscape.

Crafting Precision with Expertise

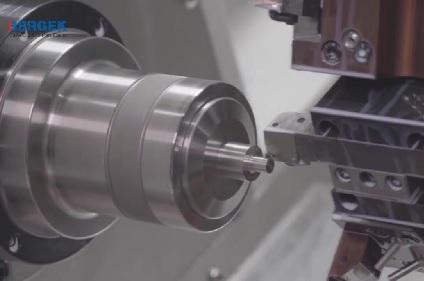

CNC machining manufacturers operate at the intersection of craftsmanship and technology, where each component is meticulously crafted with unparalleled precision. These artisans leverage their expertise to transform raw materials into intricate parts, employing advanced CNC machines to execute precise instructions with utmost accuracy. The result is a testament to their commitment to excellence, as they deliver components that meet the most stringent quality standards.

Innovating for Excellence

At the core of CNC machining is a culture of innovation that drives continuous improvement and advancement. Manufacturers are constantly exploring new techniques, materials, and processes to enhance efficiency and quality. Whether it's optimizing tool paths for faster production or integrating automation for seamless operations, CNC machining manufacturers are at the forefront of innovation, pushing the boundaries of what's possible in precision engineering.

Custom Solutions for Diverse Needs

One of the key strengths of CNC machining manufacturers lies in their ability to provide custom solutions tailored to the unique needs of each client. Whether it's a complex aerospace component or a specialized medical device, manufacturers collaborate closely with clients to understand their requirements and deliver solutions that exceed expectations. This bespoke approach not only ensures optimal performance but also fosters long-term partnerships built on trust and reliability.

Navigating Complexity with Confidence

In the dynamic landscape of modern manufacturing, CNC machining manufacturers navigate a myriad of challenges with confidence and expertise. From intricate geometries to tight tolerances, they tackle complexity head-on, leveraging their technical prowess and problem-solving skills to overcome obstacles. Whether it's adapting to evolving industry standards or addressing unforeseen production issues, manufacturers demonstrate resilience and agility in the face of adversity.

Embracing Sustainability and Efficiency

In addition to precision and quality, CNC machining manufacturers are increasingly embracing sustainability and efficiency in their operations. From optimizing material usage to reducing energy consumption, manufacturers are implementing eco-friendly practices to minimize their environmental footprint. By prioritizing sustainability, they not only contribute to a greener future but also enhance operational efficiency and cost-effectiveness.

Conclusion

In conclusion, CNC machining manufacturers play a crucial role in the modern industrial landscape, offering precision-engineered solutions that drive innovation and excellence. With their expertise, innovation, and commitment to quality, they continue to push the boundaries of what's possible, shaping industries and driving progress. As technology advances and new challenges emerge, CNC machining manufacturers will undoubtedly remain at the forefront, leading the way towards a future defined by precision, efficiency, and sustainability.