In a cooling tower, the main objective is to cool water quickly and efficiently. To achieve this, maximizing the water’s exposure to surface area is crucial. Cooling tower fill is a medium designed to increase the surface area, improving heat exchange efficiency. If you’re looking for information on cooling tower fill, this guide provides an overview of the different types commonly used in cooling towers.

Types of Cooling Tower Fill

Cooling tower fill is primarily categorized into two main types: Film Fill and Splash Fill. Each has distinct features suited for specific cooling tower designs and performance needs.

1. Film PVC Fill

Film fill consists of sheets of material, typically corrugated, that allow water to flow smoothly over its surface. The design of the corrugated pattern enables the water to spread evenly across the fill, enhancing the surface area for efficient cooling. Film fill is customizable in thickness and height, allowing it to meet specific requirements for various cooling tower models.

According to industry sources like Wearelel, nearly 50% of all cooling towers today use film fill. However, one limitation of this type of fill is its potential to clog. The narrow passages at the top of the fill may prevent the water from redistributing itself properly, which can lead to blockages over time.

Pros of Film Fill

- Maximizes water surface exposure

- Customizable to various tower specifications

Cons of Film Fill

- Prone to clogging due to narrow passages

- Limited water redistribution capacity

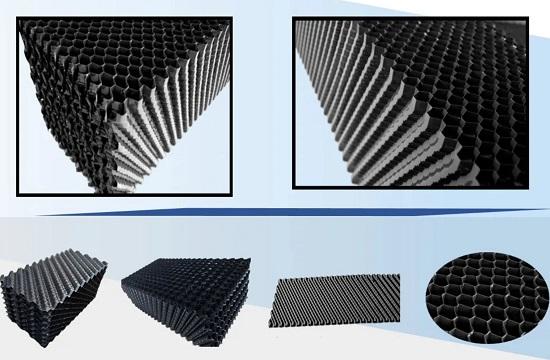

2. Splash Fill

Splash fill is designed to allow water to cascade through a series of parallel bars, redistributing itself at each level. This type of fill is commonly used in crossflow cooling towers, where horizontal airflow is not restricted. Unlike film fill, splash fill does not significantly impede the horizontal flow of air, which makes it ideal for crossflow tower designs.

One major benefit of splash fill is its tolerance for initial water distribution irregularities. It is easier to maintain than film fill, as the wide-open structure allows for straightforward visual inspection. Regular maintenance on splash fill is typically less challenging, and professionals can easily assess water flow patterns and fill conditions.

Pros of Splash Fill

- Effective water redistribution across multiple levels

- Easier to maintain and inspect

Cons of Splash Fill

- Can interrupt water flow patterns

- Less commonly available than film fill

Cooling Tower Fill Installation & Removal

Both film fill and splash fill require proper installation to ensure peak performance. Whether you need to install, replace, or remove fill materials, professional services can ensure the job is done efficiently. For installations, experts offer the right fill for both counterflow and crossflow cooling towers, ensuring optimal water cooling performance.

Crossflow vs. Counterflow Cooling Tower Fill

- Crossflow Cooling Towers: These towers feature fill materials like BXF Fill Kits, Crossflow Fill Packs, BAC Series, and Marley Series, all designed to work in crossflow tower configurations.

- Counterflow Cooling Towers: Similarly, counterflow cooling towers use fill materials including BXF Fill Kits, filler cooling tower, BAC Series, and Marley Series, specifically designed for counterflow tower designs.