In the world of industrial machinery and manufacturing, ensuring that equipment operates efficiently, reliably, and with minimal downtime is critical to profitability and safety. One company that has made significant strides in providing high-quality lubrication solutions is Isohitech. electric grease pump Through its innovative products, cutting-edge technology, and commitment to quality, Isohitech has emerged as a trusted name in industrial lubrication systems across multiple sectors. This article delves into Isohitech’s offerings, the importance of proper lubrication, and how the company contributes to enhancing industrial efficiency.

About Isohitech:

Isohitech is a leading manufacturer and supplier of lubrication systems and components. With a strong reputation for high-performance lubrication solutions, Isohitech serves industries ranging from automotive and construction to manufacturing and energy. The company specializes in designing and manufacturing lubrication systems that help prolong equipment life, reduce maintenance costs, and improve operational efficiency.

The company’s expertise spans centralized lubrication systems, oil mist systems, grease pumps, lubrication injectors, and monitoring equipment, among other products. Their solutions are designed to meet the rigorous demands of industrial machinery, ensuring smooth operation even under extreme conditions.

Importance of Industrial Lubrication:

- Equipment Longevity: Proper lubrication reduces friction between moving parts, minimizing wear and tear. This helps extend the life of critical machinery components, saving businesses from costly replacements and unplanned downtime.

- Operational Efficiency: Friction and overheating caused by poor lubrication can hinder machine performance. Isohitech’s advanced lubrication systems ensure consistent application of lubricants, enhancing efficiency and ensuring machines operate at optimal capacity.

- Maintenance Cost Reduction: Lubrication systems help prevent premature equipment failure, minimizing maintenance frequency and the associated costs. Predictive maintenance solutions, which monitor lubricant levels and quality, further enhance cost savings.

- Safety and Environmental Compliance: Proper lubrication reduces equipment malfunction risks that can lead to safety hazards in industrial environments. Additionally, controlled lubricant application reduces wastage and environmental contamination.

Isohitech Product Range:

- Centralized Lubrication Systems: Centralized lubrication systems are one of Isohitech’s flagship offerings. These systems are designed to automatically deliver precise amounts of lubricant to multiple lubrication points across machinery.

- Grease Lubrication Systems: For applications requiring thicker lubricants, Isohitech provides highly efficient grease lubrication systems. These systems are commonly used in heavy machinery such as construction equipment, mining machines, and wind turbines.

- Oil Mist Systems: Oil mist lubrication is ideal for high-speed rotating equipment such as turbines and compressors. Isohitech’s oil mist systems create a fine mist of oil that coats components evenly, reducing friction and heat generation.

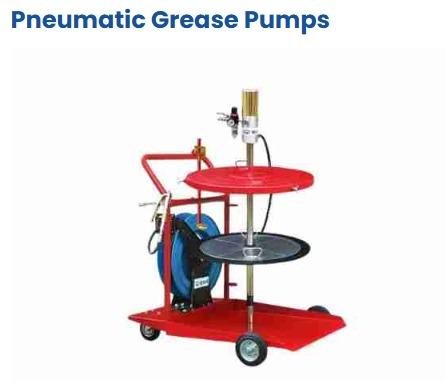

- Lubrication Pumps and Injectors: Isohitech offers a variety of manual, electric, and pneumatic pumps designed to suit diverse industrial needs. These pumps are at the heart of lubrication systems, ensuring that lubricants are delivered reliably to the right areas.

- Monitoring and Control Systems: Modern lubrication isn’t just about applying lubricants; it’s about monitoring conditions to prevent issues. Isohitech provides real-time monitoring solutions that track lubricant flow rates, pressure, and temperature.

Industries Served:

- Automotive Manufacturing: In automotive assembly lines, proper lubrication is essential for welding robots, conveyor systems, and stamping equipment. Isohitech’s lubrication solutions ensure that these machines operate reliably, minimizing production delays.

- Construction and Mining: Heavy-duty equipment in construction and mining, such as excavators, bulldozers, and crushers, require constant lubrication due to harsh operating environments. Isohitech’s robust grease systems provide the protection these machines need to perform under stress.

- Energy Sector: Turbines, compressors, and generators in power plants rely heavily on lubrication systems to prevent overheating and wear. Isohitech’s oil mist systems and central lubrication setups are ideal for ensuring consistent performance.

- Food and Beverage: Food processing equipment requires food-grade lubricants delivered through precise systems to meet safety standards. Isohitech offers solutions that comply with food safety regulations while ensuring equipment longevity.

- General Manufacturing: From metal fabrication to plastic molding, Isohitech’s lubrication systems support smooth operations across diverse manufacturing processes. By reducing friction, they enhance product quality and production efficiency.

Commitment to Quality and Innovation:

Isohitech’s success is built on a strong foundation of quality assurance, innovation, and customer support. The company invests heavily in R&D to develop lubrication technologies that not only meet current industry standards but also anticipate future needs.

Quality Assurance:

Rigorous quality control processes ensure every system meets performance and safety standards.

Use of high-grade materials for durability.

Compliance with international regulations.

Development of smart lubrication systems equipped with IoT sensors for real-time monitoring.

Customizable solutions tailored to unique customer needs.

Focus on sustainable lubrication practices, reducing environmental impact.

Customer Support:

Comprehensive training and technical support

Assistance with system design and customization.

Prompt after-sales service to ensure minimal downtime.

Case Studies

Case Study 1: Automotive Plant

An automotive manufacturer implemented Isohitech’s centralized lubrication system on its robotic assembly line. The result:

- 25% reduction in downtime.

- 15% lower lubricant consumption.

- Improved weld consistency due to reliable lubrication.

- Case Study 2: Mining Operation

A mining company adopted Isohitech’s high-pressure grease lubrication system for its fleet of excavators. Outcomes included:

- 30% increase in equipment lifespan.

- Reduction in manual lubrication tasks.

- Enhanced safety with reduced technician exposure.

- Future Outlook

As industries adopt Industry 4.0 technologies, Isohitech is well-positioned to lead the integration of smart lubrication systems with predictive maintenance platforms. These systems use sensors and analytics to predict lubrication needs, ensuring optimal performance while minimizing waste.

- Key trends shaping Isohitech’s future include:

- Adoption of biodegradable lubricants.

- Expansion into emerging markets.

- Continued innovation in wireless monitoring technologies.

Conclusion:

Isohitech has cemented itself as a trusted name in industrial lubrication solutions by providing high-quality products, innovative technology, and exceptional customer service. With a product portfolio spanning centralized lubrication systems, grease pumps, oil mist systems, and smart monitoring tools, the company addresses the diverse needs of industries ranging from automotive to energy.