In industries such as construction, manufacturing, shipping, and logistics, reliable and durable lifting equipment is crucial for ensuring safety and efficiency. XS Sling has emerged as a trusted provider of high-quality slings and rigging solutions, offering a diverse range of lifting products that meet stringent industry standards. With a focus on durability, performance, and innovation, XS Sling provides lifting solutions designed for heavy-duty applications. we will explore the products, benefits, and applications of XS Sling’s offerings, helping businesses understand why their rigging and lifting equipment is the right choice for various industrial needs.

Understanding Lifting Slings

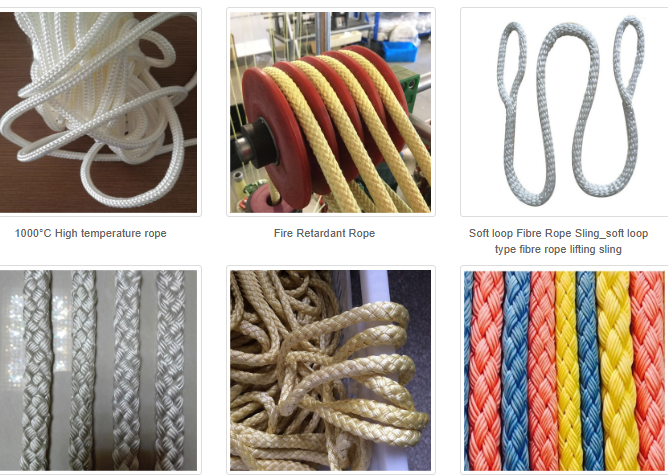

A lifting sling is a critical component in material handling and lifting operations. It connects the load to the lifting equipment, flat webbing sling ensuring safe movement and transportation of heavy objects. Lifting slings come in various materials, each designed for specific applications.

Types of Lifting Slings

Synthetic Slings – Made from polyester or nylon, these slings are lightweight, flexible, and ideal for lifting delicate or finished goods.

Wire Rope Slings – Composed of steel wire strands, they provide exceptional strength and durability for heavy lifting.

Chain Slings – Used in high-temperature and rugged environments, chain slings offer unmatched durability and adjustability.

Round Slings – A variation of synthetic slings, these feature a continuous loop construction for superior load distribution.

XS Sling specializes in manufacturing and supplying a wide variety of lifting slings to meet industry requirements.

XS Sling offers a diverse selection of rigging and lifting solutions tailored to different industries. Some of the key products include:

- Synthetic Web Slings: Made from high-strength polyester or nylon

Available in various lengths and weight capacities

Lightweight and easy to handle

Suitable for lifting fragile or polished surfaces

- Wire Rope Slings

Constructed using high-tensile steel wire

Provides exceptional strength and abrasion resistance

Ideal for heavy-duty lifting applications in construction and shipping.

Available in single or multi-leg configurations

- Chain Slings

Designed for harsh working conditions

Capable of handling high-temperature and extreme loads

Available in Grade 80, 100, and 120 chains

Customizable with various end fittings

- Round Slings

Continuous loop design for better load distribution

Resistant to UV rays and chemicals

Easy to inspect and replace when necessary

Ideal for lifting cylindrical or irregular-shaped loads

- Endless Slings

Feature continuous loops for multiple lifting configurations

Provide improved load stability

Reduce wear and tear on load-bearing surfaces

Versatile for various lifting angles and applications

Benefits of Choosing XS Sling

- Superior Quality and Durability: XS Sling ensures that all products meet high industry standards, providing durable and long-lasting lifting solutions. Their slings undergo rigorous testing to guarantee reliability and performance in demanding environments.

- Safety and Compliance: Safety is paramount in lifting operations, and XS Sling adheres to OSHA (Occupational Safety and Health Administration) and ASME (American Society of Mechanical Engineers) safety guidelines. Their slings are designed with load capacity tags, wear-resistant coatings, and reinforced stitching to enhance safety during use.

- Customizable Solutions: Every lifting task is unique, and XS Sling offers customized slings tailored to specific industry needs. Customers can choose:

- Cost-Effectiveness: XS Sling’s products are designed for long-term use, reducing frequent replacements and maintenance costs. Their slings provide an optimal balance between quality and affordability, making them a cost-effective choice for businesses.

- Easy Maintenance and Inspection: XS Sling ensures that their slings are easy to inspect and maintain. They offer:

Clear labeling for load capacity and safety information

UV-resistant coatings to extend product life

Inspection guidelines to identify wear and damage

Industries That Benefit from XS Sling

- Construction: Lifting heavy materials, steel beams, and precast concrete requires durable and high-strength slings. XS Sling provides wire rope slings, chain slings, and web slings for safe lifting in construction projects.

- Manufacturing: Factories and production facilities use XS Sling’s lifting solutions for assembly lines, material transportation, and machine handling.

- Shipping and Logistics: Ports and freight companies rely on strong, corrosion-resistant slings for moving heavy cargo and shipping containers.

- Oil and Gas Industry: The oil and gas sector demands heat-resistant and durable slings for lifting pipes, machinery, and offshore equipment.

- Aerospace Industry: Handling aircraft components requires precision lifting solutions. XS Sling provides customized round slings and synthetic slings for aerospace applications.

Choosing the right lifting sling is critical for safety and efficiency. Here are factors to consider:

Load Weight – Select a sling with a weight capacity higher than the load being lifted.

Material Type – For heavy and high-temperature environments, chain slings are ideal. For delicate loads, synthetic slings are better.

Environmental Conditions – Oil-resistant, UV-protected, and corrosion-resistant slings are ideal for extreme environments.

Sling Configuration – Choose between single-leg, multi-leg, endless, or adjustable slings based on lifting requirements.

Inspection Requirements – Regularly inspect slings for wear, fraying, or damage to maintain safety.

Conclusion

XS Sling is a leading provider of high-quality lifting and rigging solutions, offering products tailored for multiple industries. Their commitment to safety, durability, and performance makes them a trusted choice for businesses handling heavy lifting operations. With a comprehensive range of slings, including synthetic web slings, wire rope slings, chain slings, and round slings, XS Sling ensures that customers find the perfect lifting solution for their needs.