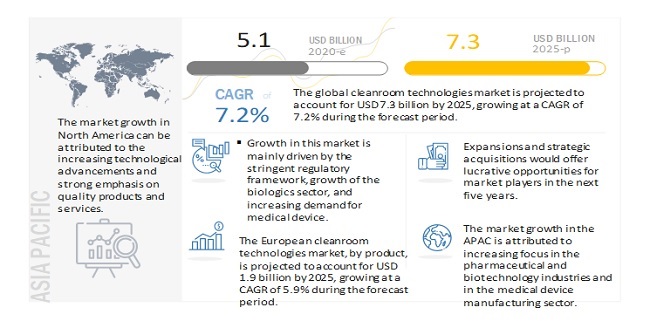

The growth of this market is majorly driven by the stringent regulatory framework, growth of the biologics sector, rising demand for sterilized pharmaceutical formulations, increasing demand for medical devices, and technological advancements in cleanroom technology. Also, the increasing demand in developing economies and the growing focus on energy-efficient cleanrooms are expected to offer significant opportunities for market growth in the coming years. However, the high operational cost associated with the cleanrooms is expected to restrain market growth to a certain extent.

With the increasing demand for certified products, various quality certifications such as ISO checks and National Safety and Quality Health Standards (NSQHS) have been made mandatory for ensuring that the standards for manufacturing processes and products are being upheld. The quality certifications require products to be processed in a cleanroom environment to ensure minimum possible contamination.

Also, the price per square foot is not the same for ISO 6 and ISO 8 cleanrooms. This is because the amount of air supplied is different in both classes of cleanrooms. The air is 100 times cleaner in an ISO 6 cleanroom than in an ISO 8 cleanroom, thereby doubling the air conditioning capacity of the HVAC systems.

For More Information Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=263122482

Emerging Asian and Latin American markets are expected to offer significant growth opportunities for players operating in the cleanroom technologies market, primarily due to the presence of less-stringent regulatory policies, an increasing number of pharmaceutical companies, availability of a skilled workforce, government initiatives to boost local manufacturing, and lower cost of clinical trials in these countries. Biomedical research is considered as an economic growth area in the Asia Pacific, and governments provide financial support in this domain.

Cleanrooms are mostly designed according to customer requirements based on product specifications and customer-specific design requirements. However, there are no specific guidelines for cleanroom designs for different application areas or product types. This leads to several challenges for cleanroom manufacturers, as they need to follow different designs every time.

Furthermore, regulations do not provide requirements regarding the environmental, product, or facility parameters that are to be controlled. Instead, they only provide standards that a company needs to meet after it decides to manufacture a product using a cleanroom environment.

This is mainly due to the higher demand for hardwall cleanrooms, as they are more design-flexible than standard and softwall cleanrooms, quick and easy to install, freestanding for easy portability, and easy to expand or reconfigure.