PVC (Polyvinyl chloride) is widely used in electrical cable construction for insulation, bedding and sheathing. It was the 1950s when PVC started to replace rubber insulated and sheathed cables in general household wiring due to its ease of processing. PVC is cost-effective and also has excellent ageing properties and typically exceeds a 25 to 30 year service life.

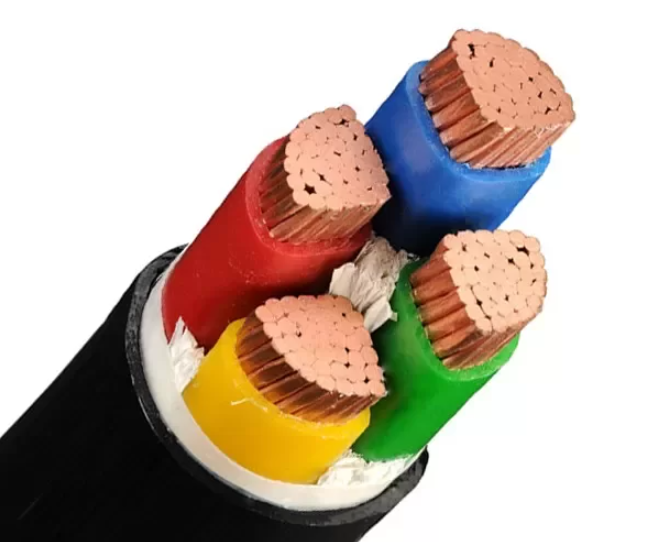

PVC insulated cables features

It’s considered to be one of the most versatile of the common thermoplastics due to the fact that its properties can be easily modified - although PVC is inherently hard and rigid it is easily modified with plasticizers, stabilizers, lubricants and various other ingredients and fillers that aid processing and enhance various properties. It is also easy to process and recycle when used as a thermoplastic type.

Cable with a PVC insulation or sheathing is flame retardant, which is an important consideration for electric cables in most applications. PVC can be made resistant to a wide range of chemicals including oils, acids and alkalis, and is tough, durable and resistant to abrasion. The addition of various additives can improve its temperature range, typically from -40 to 105°C, as well as the resistance to sunlight, reduced smoke emission and improved water resistance.

As an insulation material cables often come down to a choice between XLPE vs PVC - between a thermoplastic and a thermoset material. There are thermoset versions of PVC which are cross-linked, typically with electron beam technology but they are more expensive to use and so when specified they are typically in high-spec applications in industries such as defence and automotive. The thermoset or cross-linked PVC has improved temperature resistance, is tougher, and has a better dielectric strength, which means that a thinner coating or insulation layer can be applied making the overall cable dimension smaller.