Looking for a highly efficient and cost-effective way to transfer heat between fluids? Look no further than brazed plate heat exchangers! These marvels of engineering are widely used across a variety of fields, from HVAC systems to refrigeration and beyond. So if you're curious about where this versatile technology is making waves right now, keep reading – we've got all the details you need!

What is a brazed plate heat exchanger?

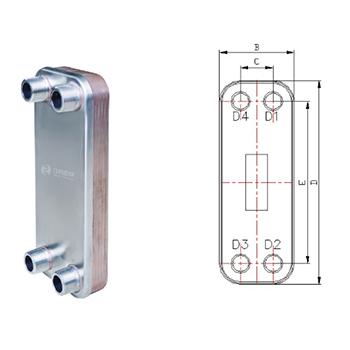

A brazed plate heat exchanger (BPHE) is a type of heat exchanger that uses metal plates to transfer heat between two fluids. The plates are brazed together with a high-temperature alloy, which creates a strong seal that can withstand high pressures. BPHEs are widely used in a variety of industries, including HVAC, food and beverage processing, pharmaceutical manufacturing, and chemical processing.

BPHEs are highly efficient heat exchangers due to their large surface area and the ability to operate at high pressures. They are also compact and lightweight, which makes them easy to install and maintain. BPHEs typically have a long lifespan and require little maintenance.

How do brazed plate heat exchangers work?

Brazed plate heat exchangers are made up of a series of stainless steel plates that are brazed together at high temperatures using a bronze or nickel alloy. The spaces between the plates are filled with a specially designed gasket material that allows for thermal expansion. The plate pack is then placed in a pressure vessel and sealed.The fluid to be heated or cooled is pumped through the heat exchanger, and the heat is transferred between the fluid and the plates. As the fluid passes through the narrow channels between the plates, its resistance to flow creates turbulence, which maximizes the heat transfer between the fluid and the plates.

What are the benefits of using a brazed plate heat exchanger?

There are many benefits of using a brazed plate heat exchanger, such as:

-They have a very high thermal efficiency due to their large surface area.

-They are easy to clean and maintain.

-They are less likely to leak than other types of heat exchangers.

-They are compact and lightweight.

-They can be used in a wide range of applications.

In which fields are brazed plate heat exchangers widely used?

Brazed plate heat exchangers are widely used in a variety of industries where there is a need for efficient heat transfer. Some of the most common industries that use brazed plate heat exchangers include:

-HVAC: Brazed plate heat exchangers are often used in heating, ventilation, and air conditioning systems to transfer heat between two fluids.

-Refrigeration: Brazed plate heat exchangers can be used in refrigeration systems to transfer heat between the refrigerant and another fluid, such as water or glycol.

-Power generation: Brazed plate heat exchangers are commonly used in power plants to transfer heat between the steam and water circuits.

-Chemical processing: In chemical plants, brazed plate heat exchangers are often used to transfer heat between two process fluids, such as chemicals or acids.

How to choose the right brazed plate heat exchanger?

Brazed plate heat exchangers (BPHEs) are widely used in a number of industries because of their high thermal efficiency and compact design. When choosing a BPHE, it is important to consider the specific application and the desired performance parameters.The first step is to define the process requirements, such as maximum allowable pressure and temperature, as well as corrosion allowance. The next step is to determine the heat-transfer area needed for the application. This can be done by estimating the required heat duty or using process simulation software.After the heat-transfer area has been determined, the type of BPHE can be selected based on its ability to meet the process requirements. There are three main types of BPHEs: single-wall, double-wall, and welded plate. Single-wall BPHEs are typically used for low-pressure applications where there is no risk of thermal shock. Double-wall BPHEs are suitable for high-pressure applications and provide a higher level of safety than single-wall BPHEs. Welded plate BPHEs offer the highest level of safety and are often used in critical applications such as nuclear power plants.Once the type of BPHE has been selected, the material must be chosen based on compatibility with the process fluid. Common materials include stainless steel, carbon steel, copper, nickel, and titanium. The material selection must take into account both corrosion resistance and thermal conductivity.

Conclusion

Brazed plate heat exchangers are widely used in a variety of industries, from chemical production to pharmaceutical processing. They offer a reliable and cost-effective cooling solution that can help keep temperatures under control and maintain high efficiency levels. Whether you're looking for something to cool your manufacturing process or provide condenser support in your air conditioning system, brazed plate heat exchangers have the capability to tackle whatever challenge comes their way. Investing in one is definitely worth considering if you want an efficient and durable heating exchange solution.Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD. was established in Jiangyin City (China) in 2013. The company is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and production.zy@jsyuanzhuo.com