Welcome to the world of efficient heat exchange! If you've ever wondered how industries keep their processes running smoothly and sustainably, then you're in for a treat. Today, we're diving deep into the design and performance of GPHE B250B Gasketed Plate Heat Exchangers – the unsung heroes behind many industrial operations. Get ready to uncover the secrets behind these innovative devices that are revolutionizing heat transfer efficiency like never before. So buckle up, because we're about to embark on an exciting journey into the fascinating world of GPHE B250B Gasketed Plate Heat Exchangers!

What are GPHE B250B Gasketed Plate Heat Exchangers?

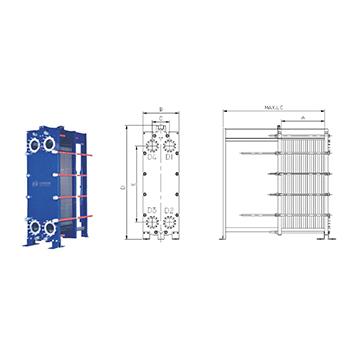

https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-B250B.shtml are highly efficient devices used in various industries to transfer heat between two fluids. They consist of a series of plates with gaskets that create separate flow channels for each fluid. These heat exchangers are designed to maximize the surface area available for heat exchange, allowing for optimal thermal performance.

The beauty of GPHE B250B lies in its versatility. It can handle a wide range of applications, from heating and cooling processes to waste heat recovery and even refrigeration systems. Whether you're working in chemical plants, power generation facilities, or HVAC systems, these plate heat exchangers offer an effective solution.

One key advantage is their compact design compared to traditional shell-and-tube heat exchangers. The stacked plate configuration allows for a larger surface area within a smaller footprint, making them space-saving options – perfect when real estate is at a premium.

What sets GPHE B250B apart from other plate heat exchangers is its exceptional efficiency. The turbulent flow created by the corrugated plates enhances the overall heat transfer coefficient, ensuring quick and efficient thermal exchange between the fluids. This translates into energy savings and reduced operating costs for industrial processes.

Another noteworthy feature is their easy maintenance. Thanks to the gasketed design, individual plates can be easily accessed and cleaned or replaced if needed without dismantling the entire unit – minimizing downtime and maximizing productivity.

In short, GPHE B250B Gasketed Plate Heat Exchangers are reliable workhorses known for their high-performance capabilities across diverse industries. With their compact size, energy efficiency, and ease of maintenance, they continue to play a vital role in enhancing operational efficiency while keeping costs in check.

How do GPHE B250BGasketed Plate Heat Exchangers Work?

Gasketed Plate Heat Exchangers, like the GPHE B250B model, are fascinating pieces of engineering that play a crucial role in various industries. But how exactly do they work?

At the heart of these heat exchangers are multiple plates stacked together with gaskets in between. The hot and cold fluids flow through alternate channels formed by these plates. As the fluids pass through, heat is transferred from one medium to the other.

The design allows for efficient heat transfer due to the large surface area provided by the numerous plates. Additionally, turbulence is created within the channels, further enhancing heat exchange.

One key feature of gasketed plate heat exchangers is their flexibility. The number of plates can be adjusted based on specific process requirements, allowing for customization and optimization of performance.

The gaskets used in these heat exchangers ensure a tight seal between each plate to prevent any cross-contamination between the two fluids being exchanged. This prevents leaks and ensures efficiency and safety.

To maintain optimal performance, regular maintenance is necessary to inspect and replace worn-out gaskets or damaged plates if needed.

GPHE B250B Gasketed Plate Heat Exchangers operate by utilizing multiple plates with gaskets to facilitate efficient transfer of heat between two fluid streams while maintaining proper sealing integrity. These versatile devices offer great potential for various industrial applications requiring effective temperature control and energy efficiency without compromising safety or productivity.

Design of GPHE B250BGasketed Plate Heat Exchangers

The design of GPHE B250B Gasketed Plate Heat Exchangers is a key factor in their efficient and effective performance. These heat exchangers are composed of multiple plates that are pressed together, creating narrow channels for the fluid to flow through. The plates themselves have strategically placed gaskets, which ensure that each channel remains sealed and prevents any mixing of fluids.

One important aspect of the design is the plate pattern. It determines how the fluid flows within the heat exchanger, maximizing heat transfer while minimizing pressure drop. The plate patterns can vary depending on the specific application and desired performance.

Another crucial design element is the material used for both the plates and gaskets. Stainless steel is commonly used for its durability, resistance to corrosion, and thermal conductivity properties. Meanwhile, elastomers like EPDM or NBR are often chosen for their flexibility and ability to withstand high temperatures.

Additionally, GPHE B250B heat exchangers feature an innovative frame design that provides stability while allowing easy access to clean or replace individual plates if necessary. This modular construction makes maintenance much simpler compared to other types of heat exchangers.

With their well-thought-out design features such as plate patterns, material selection, and accessible frames – GPHE B250B Gasketed Plate Heat Exchangers offer optimal performance in various applications from HVAC systems to industrial processes without compromising efficiency or reliability.

Performance of GPHE B250BGasketed Plate Heat Exchangers

The performance of GPHE B250B Gasketed Plate Heat Exchangers is truly impressive. These heat exchangers are designed to efficiently transfer heat between two fluid streams, making them ideal for a wide range of applications.

One key factor that contributes to their high performance is the innovative plate design. The plates have special patterns and corrugations that create turbulence in the flow, maximizing heat transfer efficiency. This means that more heat can be transferred in a shorter amount of time, resulting in faster heating or cooling processes.

Additionally, GPHE B250B Gasketed Plate Heat Exchangers offer excellent thermal conductivity due to the use of materials such as stainless steel or titanium for the plates. This ensures optimal heat transfer across the plate surface area, minimizing any potential energy loss.

Furthermore, these heat exchangers are highly versatile and can handle both high and low temperature differentials with ease. They are also capable of handling varying flow rates without compromising performance.

Another noteworthy aspect is their compact size compared to traditional shell-and-tube heat exchangers. The compact design allows for easy installation even in limited space environments while still delivering exceptional performance.

Moreover, GPHE B250B Gasketed Plate Heat Exchangers require minimal maintenance thanks to their gasket system which provides a reliable seal between plates without leaks or cross-contamination between fluids.

In conclusion (not concluding), the outstanding performance of GPHE B250B Gasketed Plate Heat Exchangers makes them an excellent choice for industries seeking efficient and reliable heat exchange solutions. Whether it's heating or cooling applications, these innovative devices consistently deliver impressive results!

Advantages and Disadvantages of GPHE B250BGasketed Plate Heat Exchangers

Advantages and disadvantages are essential aspects to consider when evaluating the suitability of GPHE B250B Gasketed Plate Heat Exchangers for your specific needs. Let's take a closer look at both sides of the coin.

One significant advantage of these heat exchangers is their compact design. The plate arrangement allows for a large surface area within a relatively small footprint, making them an ideal choice for installations where space is limited or costly.

Another advantage lies in their efficiency. GPHE B250B models offer excellent heat transfer capabilities, enabling efficient energy exchange between two fluids. This can result in lower energy consumption and reduced operating costs over time.

Additionally, gasketed plate heat exchangers are known for their flexibility. With removable plates, they allow for easy inspection, maintenance, and potential expansion if needed in the future. This feature can save valuable time during servicing or upgrades.

On the flip side, one disadvantage to consider is that gaskets may wear out over time due to exposure to high temperatures and aggressive fluids. Regular inspections and replacements are necessary to ensure optimal performance and prevent leakage issues.

Furthermore, some applications may require higher thermal efficiency than what gasketed plate heat exchangers can provide. In such cases, alternative types of heat exchangers with different designs might be more suitable.

It's important to note that every application has unique requirements and constraints which should be carefully considered before choosing any type of heat exchanger system like GPHE B250B Gasketed Plate Heat Exchangers.

Conclusion

In this article, we have explored the design and performance of GPHE B250B Gasketed Plate Heat Exchangers. These heat exchangers offer an efficient and reliable solution for various industrial applications.

GPHE B250B Gasketed Plate Heat Exchangers are designed to maximize heat transfer while minimizing pressure drop. Their unique plate design ensures optimal turbulence, allowing for excellent thermal efficiency. With a wide range of plate options available, these heat exchangers can be customized to meet specific application requirements.

The performance of GPHE B250B Gasketed Plate Heat Exchangers is impressive. They provide high heat transfer coefficients which result in improved energy efficiency and reduced operating costs. The gaskets used in these heat exchangers are durable and resistant to extreme temperatures, ensuring long-term reliability.

One notable advantage of GPHE B250B Gasketed Plate Heat Exchangers is their compact size compared to other types of heat exchanger systems. This not only saves space but also simplifies installation and maintenance processes.

However, it's important to consider some potential disadvantages as well. The use of gaskets means that there is a possibility of leakage over time, although regular inspection and maintenance can help mitigate this risk. Additionally, the intricate plate design may require specialized cleaning procedures to ensure optimum performance.

GPHE B250B Gasketed Plate Heat Exchangers offer a highly efficient and versatile solution for industrial heating and cooling applications. Their compact size, excellent thermal efficiency, customizable options make them a preferred choice for many industries worldwide.

So whether you need robust heating solutions or effective cooling capabilities for your operations, considering GPHE B250B Gasketed Plate Heat Exchangers could be a smart move towards achieving optimal performance while maximizing energy savings.Welcome to contact us.zy@jsyuanzhuo.com