Thehttps://www.yojointernational.com/Brazed-Plate-Heat-Exchanger/ is a highly efficient and compact device used for heat transfer in various industries. In this article, we will delve deeper into the technology, advantages, applications, and key features of BPHEs. Whether you are an engineer, industry professional, or business owner, understanding the benefits and capabilities of BPHEs can help you make informed decisions and optimize your heat transfer processes.

I. What is a Brazed Plate Heat Exchanger

A. Definition and Functionality:

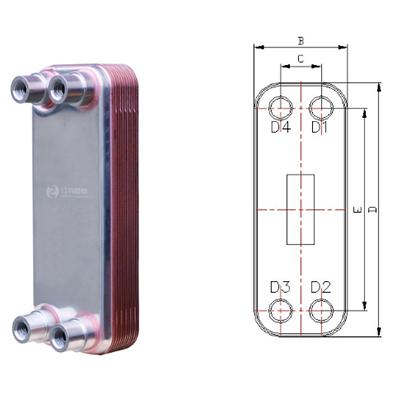

1. A BPHE is a type of heat exchanger that transfers heat between two fluids, without direct contact between them.

2. It consists of a series of stainless steel plates stacked together and brazed at the edges using copper or nickel.

3. The fluid channels created by the plates allow for efficient heat exchange while maintaining separation between the two fluids.

B. How Does it Work?

1. The hot and cold fluids flow through separate channels formed by the corrugated plates.

2. As the fluids pass through the channels, heat is transferred from the hotter fluid to the cooler fluid through the thin plates.

3. The specific plate design ensures turbulent flow, maximizing heat transfer efficiency.

II. Advantages of Brazed Plate Heat Exchangers

A. Compact and Space-Saving Design:

1. BPHEs offer high thermal efficiency in a small footprint, making them ideal for installations with limited space.

2. The compact size also reduces material requirements and decreases shipping and installation costs.

B. High Heat Transfer Efficiency:

1. The corrugated plate design creates turbulent flow, increasing heat transfer rates compared to traditional shell-and-tube heat exchangers.

2. The close proximity of the plates promotes efficient heat exchange, resulting in reduced energy consumption.

C. Durability and Reliability:

1. BPHEs are fabricated using high-quality stainless steel plates and brazing materials, ensuring resistance to corrosion and mechanical stress.

2. The absence of gaskets or seals eliminates the risk of leakage, increasing the overall reliability and lifespan of the exchanger.

D. Cost-Effective Solution:

1. Due to their compact size, BPHEs require less refrigerant, reducing operating costs in refrigeration and air conditioning applications.

2. The efficient heat transfer capability leads to reduced energy consumption, resulting in long-term cost savings.

III. Applications of Brazed Plate Heat Exchangers

A. HVAC and Refrigeration:

1. BPHEs are widely used in heating, ventilation, and air conditioning systems, efficiently transferring heat between the refrigerant and the surrounding space.

2. They are also employed in refrigeration applications, ensuring optimal cooling performance with minimal energy usage.

B. Industrial Processes:

1. BPHEs find applications in various industrial processes, such as oil and gas, chemical manufacturing, and power generation.

2. They are used for heat recovery, preheating, and cooling purposes, contributing to energy conservation and process optimization.

C. Domestic Hot Water:

1. BPHEs are utilized in residential and commercial settings for heating domestic hot water.

2. Their compact size and high efficiency make them an ideal choice for instantaneous hot water production.

IV. Key Features to Consider when Choosing a Brazed Plate Heat Exchanger

A. Thermal Performance:

1. Look for BPHEs with high heat transfer coefficients and low pressure drops to optimize energy efficiency.

2. Evaluate the heat capacity and size range to ensure compatibility with your specific application requirements.

B. Construction and Material Quality:

1. Consider BPHEs that use stainless steel plates and high-quality brazing materials to ensure durability and resistance to corrosion.

2. Verify compliance with relevant industry standards

C. Design and Flexibility:

1. Look for BPHEs with a modular design that allows for easy expansion or modification of the heat exchanger system.

2. Consider the flexibility of the BPHE in terms of its ability to handle different flow rates, temperatures, and pressures.

D. Maintenance and Serviceability:

1. Choose a BPHE that is easy to clean and maintain, with accessible plates and connections.

2. Consider the availability of replacement parts and the ease of servicing the heat exchanger in case of any issues.

E. Cost and Value:

1. Evaluate the initial cost of the BPHE and compare it to its expected lifespan and energy efficiency to determine its overall value.

2. Consider the long-term cost savings that can be achieved through improved energy efficiency and reduced maintenance requirements.

When choosing a brazed plate heat exchanger (BPHE), there are several key features to consider to ensure that you select the right one for your specific application. One of the most important factors to consider is the thermal performance of the BPHE. Look for BPHEs with high heat transfer coefficients and low pressure drops to optimize energy efficiency. Additionally, evaluate the heat capacity and size range to ensure compatibility with your specific application requirements.

Another important factor to consider is the construction and material quality of the BPHE. Choose BPHEs that use stainless steel plates and high-quality brazing materials to ensure durability and resistance to corrosion. Verify compliance with relevant industry standards to ensure that the BPHE meets the necessary safety and quality requirements.

Design and flexibility are also important factors to consider when choosing a BPHE. Look for BPHEs with a modular design that allows for easy expansion or modification of the heat exchanger system. Consider the flexibility of the BPHE in terms of its ability to handle different flow rates, temperatures, and pressures.

Maintenance and serviceability are also important considerations. Choose a BPHE that is easy to clean and maintain, with accessible plates and connections. Consider the availability of replacement parts and the ease of servicing the heat exchanger in case of any issues.

Finally, cost and value are important factors to consider. Evaluate the initial cost of the BPHE and compare it to its expected lifespan and energy efficiency to determine its overall value. Consider the long-term cost savings that can be achieved through improved energy efficiency and reduced maintenance requirements.

Ⅴ.Conclusion

In conclusion, when choosing a brazed plate heat exchanger, it is important to consider a range of factors including thermal performance, construction and material quality, design and flexibility, maintenance and serviceability, and cost and value. By carefully evaluating these factors, you can select the right BPHE for your specific application, ensuring optimal energy efficiency and performance.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.Welcome to inquiry if you need to know more about brazed plate heat exchanger details or order wholesale.

Email:zy@jsyuanzhuo.com