UV LED technology has emerged as a revolutionary solution in numerous industries, offering enhanced efficiency, durability, and sustainability. With the growing need for energy-efficient and environmentally friendly solutions, companies like Yanso Technology Co., Limited have taken the lead in providing high-quality uv led curing systems solution. From industrial curing to medical applications, UV LED technology is transforming the way businesses operate. This article explores the advantages, applications, and future potential of UV LED technology.

Understanding UV LED Technology:

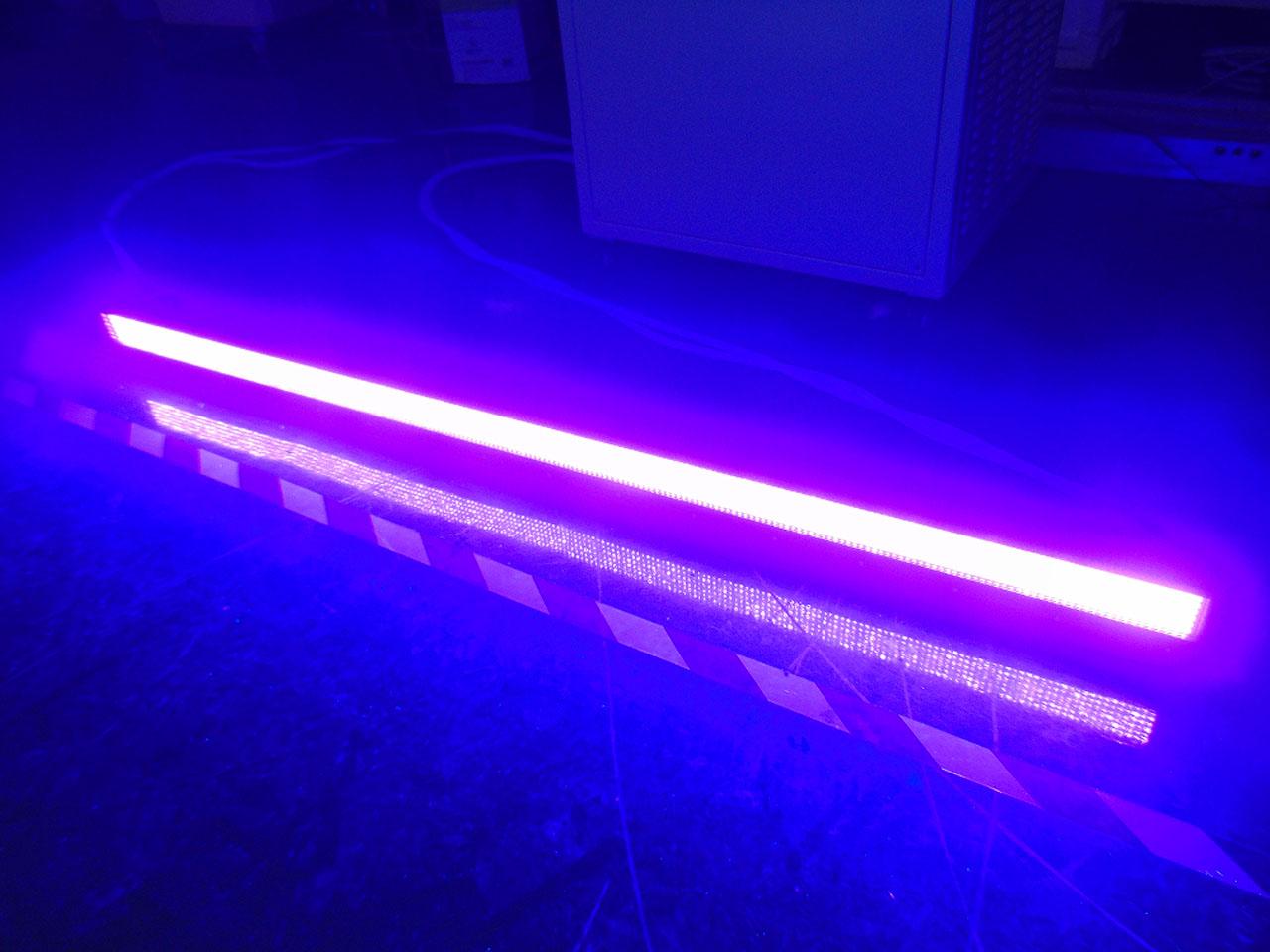

UV LED technology utilizes light-emitting diodes (LEDs) that emit ultraviolet (UV) light. Unlike traditional UV lamps, which use mercury-based bulbs, UV LEDs are solid-state devices that generate light through semiconductor materials. The primary UV wavelength categories include:

UVA (315–400 nm): Used for printing, curing, counterfeit detection, and forensics.

UVB (280–315 nm): Commonly applied in medical treatments such as phototherapy for skin conditions.

UVC (100–280 nm): Recognized for its germicidal properties, widely used in sterilization and disinfection applications.

The transition from conventional UV lamps to UV LED technology has been driven by the need for safer, more energy-efficient solutions. Companies like Yanso Technology have played a pivotal role in advancing these innovations.

Advantages of UV LED Solutions:

- Energy Efficiency: UV LED systems consume significantly less power than traditional mercury-based UV lamps. This reduction in energy consumption translates to lower operational costs and a smaller carbon footprint.

- Longer Lifespan: UV LEDs have a much longer lifespan compared to conventional UV lamps. While mercury lamps may last around 1,000 to 2,000 hours, UV LEDs can operate for over 10,000 hours, minimizing maintenance and replacement costs.

- Environmental Benefits: Traditional UV lamps contain mercury, a hazardous substance that poses environmental risks. UV LEDs eliminate this issue, offering a safer and more eco-friendly alternative.

- Instant On/Off Functionality: Unlike traditional UV lamps that require warm-up and cool-down periods, UV LEDs can be turned on and off instantly. This feature enhances productivity and reduces downtime in industrial applications.

- Lower Heat Emission: UV LED technology generates significantly less heat, making it suitable for applications that require precise temperature control. This feature is particularly beneficial in sensitive industries like electronics and medical device manufacturing.

Applications of UV LED Technology:

- Printing and Packaging: One of the most widespread applications of UV LED curing is in the printing industry. led uv dryer lamp curing systems are used to dry inks instantly, enhancing print quality and efficiency. Unlike conventional curing methods, UV LEDs prevent paper distortion and color fading, making them ideal for high-speed printing processes.

- Adhesive and Coating Curing: UV LED curing is extensively used in industries that require rapid bonding and protective coatings. Applications include: Electronics manufacturing – UV LED curing ensures strong adhesive bonds in circuit boards and electronic components. Automotive industry – Used in the application of protective coatings on vehicle parts. Furniture and wood coatings – Enhances durability and aesthetic appeal while reducing drying times.

- Medical Device Manufacturing: In the medical industry, UV LED curing systems are used to manufacture precision medical devices, ensuring fast curing of adhesives and coatings. This technology helps maintain stringent industry standards while improving production efficiency.

- Sterilization and Disinfection: With the increasing demand for effective disinfection solutions, UVC LED technology has gained prominence in sterilization applications. UVC LEDs are used to:

Disinfect water and air – Killing bacteria and viruses without harmful chemicals.

Sterilize medical equipment – Ensuring hospital tools are free from contaminants.

Sanitize surfaces – Providing touch-free sterilization solutions for various industries.

- Optical Inspection and Counterfeit Detection: UV LED technology is widely used in security applications such as forensic analysis, counterfeit detection, and quality control inspections. Businesses and government institutions rely on UV light to authenticate documents, banknotes, and valuable assets.

Yanso Technology: Leading the UV LED Industry:

- Comprehensive Product Range: Yanso Technology specializes in the research, development, and manufacturing of cutting-edge UV LED curing systems. Their product portfolio includes:

UV LED curing lamps – Designed for printing, adhesives, and industrial coatings.

Air-cooled and water-cooled curing systems – Offering versatility for different applications.

Custom UV LED modules – Tailored solutions for specific industry requirements.

- Customization and OEM/ODM Services: Understanding that different industries have unique needs, Yanso offers customized UV LED solutions. Their R&D team works closely with clients to develop tailored products, ensuring seamless integration and optimal performance.

- Global Reach and Market Presence: Yanso Technology’s products are utilized in multiple countries, including the United States, Germany, Japan, and Thailand. Their commitment to innovation and customer satisfaction has positioned them as a trusted global supplier.

Future of UV LED Technology:

As technology advances, UV LEDs are expected to continue evolving. Some anticipated developments include:

Increased efficiency and higher power output – Allowing for even faster curing times and broader industrial applications.

Enhanced wavelength precision – Improving performance in specialized applications such as medical diagnostics.

Integration with smart systems – AI-driven UV LED solutions for automated curing and sterilization processes.

Expanded adoption in consumer applications – Growth in household water purification and personal sterilization devices.

Conclusion:

UV LED technology is reshaping industries by offering energy-efficient, environmentally friendly, and high-performance solutions. With its numerous advantages and diverse applications, the demand for UV LED curing systems will only continue to grow. Yanso Technology Co., Limited remains at the forefront of this innovation, providing state-of-the-art UV LED solutions tailored to meet the evolving needs of various industries. As businesses transition to more sustainable and efficient technologies, UV LEDs will play a crucial role in driving progress and ensuring a greener future.