VMC 1580 CNC Vertical Machining Center

https://www.josencnc.com/VMC-1580-CNC-Vertical-Machining-Center.html

The machine is suitable for automobile and locomotive parts production, aviation, communication electronics, various types of precision mold processing and other fields. The bed adopts high rigidity structure, which makes the internal force structure more optimized and ensures the rigidity and thermal stability of the whole machine. The spindle box adopts balance cylinder counterweight to avoid vibration when running at high speed.

1.This model is suitable for mass production of automobile and locomotive parts, aerospace and communication electronics, automation parts processing, and various types of precision mold processing.

2.The base, slide, table, column, spindle box and other major foundation parts are made of high rigidity cast iron structure, and the internal reinforcement bars are distributed in a mesh structure to ensure the high rigidity of the foundation parts and the anti-bending and anti-vibration performance.

3.The X and Y axes adopt heavy-duty 45mm roller rail, and the Z axis adopts 55mm roller rail, which makes the machine stronger in terms of load bearing capacity and cutting performance, and the Y axis saddle adopts four-rail full support, which is stable and reliable.

4.The spindle box adopts balance bar counterweight to ensure no shaking when the spindle box is shifted quickly and to ensure the accuracy of movement.

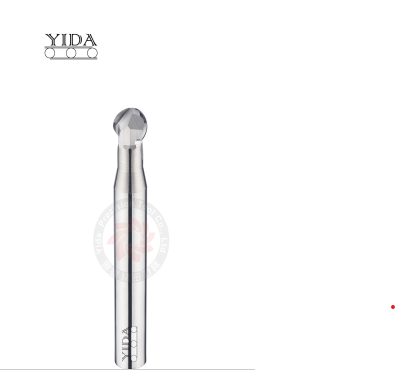

5.The spindle is equipped with belt type 8000rpm as standard, no noise and low vibration, suitable for high speed milling and tapping.

https://www.josencnc.com/VMC-1580-CNC-Vertical-Machining-Center.html

The machine is suitable for automobile and locomotive parts production, aviation, communication electronics, various types of precision mold processing and other fields. The bed adopts high rigidity structure, which makes the internal force structure more optimized and ensures the rigidity and thermal stability of the whole machine. The spindle box adopts balance cylinder counterweight to avoid vibration when running at high speed.

1.This model is suitable for mass production of automobile and locomotive parts, aerospace and communication electronics, automation parts processing, and various types of precision mold processing.

2.The base, slide, table, column, spindle box and other major foundation parts are made of high rigidity cast iron structure, and the internal reinforcement bars are distributed in a mesh structure to ensure the high rigidity of the foundation parts and the anti-bending and anti-vibration performance.

3.The X and Y axes adopt heavy-duty 45mm roller rail, and the Z axis adopts 55mm roller rail, which makes the machine stronger in terms of load bearing capacity and cutting performance, and the Y axis saddle adopts four-rail full support, which is stable and reliable.

4.The spindle box adopts balance bar counterweight to ensure no shaking when the spindle box is shifted quickly and to ensure the accuracy of movement.

5.The spindle is equipped with belt type 8000rpm as standard, no noise and low vibration, suitable for high speed milling and tapping.

VMC 1580 CNC Vertical Machining Center

https://www.josencnc.com/VMC-1580-CNC-Vertical-Machining-Center.html

The machine is suitable for automobile and locomotive parts production, aviation, communication electronics, various types of precision mold processing and other fields. The bed adopts high rigidity structure, which makes the internal force structure more optimized and ensures the rigidity and thermal stability of the whole machine. The spindle box adopts balance cylinder counterweight to avoid vibration when running at high speed.

1.This model is suitable for mass production of automobile and locomotive parts, aerospace and communication electronics, automation parts processing, and various types of precision mold processing.

2.The base, slide, table, column, spindle box and other major foundation parts are made of high rigidity cast iron structure, and the internal reinforcement bars are distributed in a mesh structure to ensure the high rigidity of the foundation parts and the anti-bending and anti-vibration performance.

3.The X and Y axes adopt heavy-duty 45mm roller rail, and the Z axis adopts 55mm roller rail, which makes the machine stronger in terms of load bearing capacity and cutting performance, and the Y axis saddle adopts four-rail full support, which is stable and reliable.

4.The spindle box adopts balance bar counterweight to ensure no shaking when the spindle box is shifted quickly and to ensure the accuracy of movement.

5.The spindle is equipped with belt type 8000rpm as standard, no noise and low vibration, suitable for high speed milling and tapping.

0 Comments

0 Shares