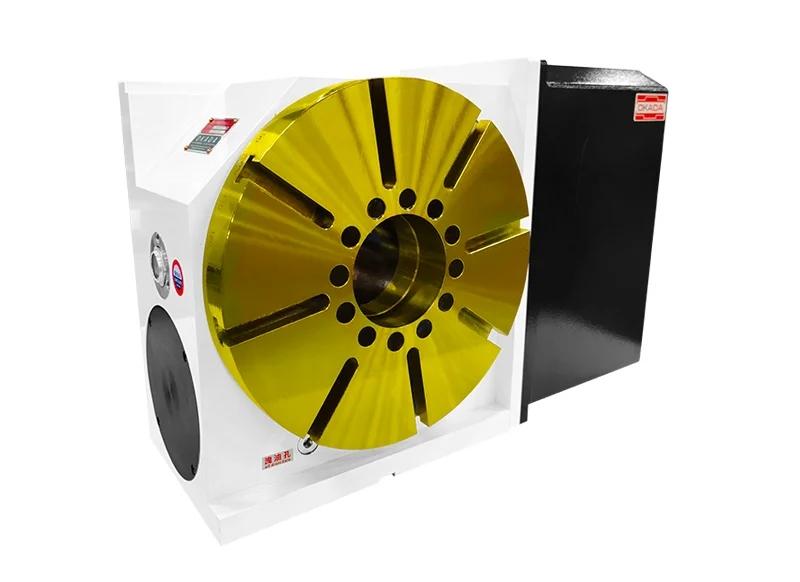

Customized Multi-disc Screw Press Dehydrator Our History Wuxi Qiuyuan Environmental Engineering Co., Ltd, locating in China Environmental Town, Yixing city, is a specialized in designing, installation and commissioning full project for industry wastewater treatment, sewage water treatment and odorous air (VOCs) abatement solutions. Our Factory Wuxi Qiuyuan Environmental Protection Engineering Co., Ltd. Brand is Bioetp ,Specializes in the engineering design and equipment manufacturing of industrial wastewater and waste gas treatment, and provides customers with stable, economic and low energy consumption solutions. Located in Yixing City, Jiangsu Province, China's environmental protection city, Bioetp specialized screw press sludge dewatering machine manufacturer, and provides installation, commissioning and operation services for customers. Bioetp has established cooperative relations with domestic well-known universities such as Zhejiang University and Nanjing University of technology to provide customers with continuous and reliable technical support and solve various difficult and miscellaneous problems of environmental protection. Bioetp combines the latest technology and rich experience to create high-quality, durable, energy-saving and efficient products for customers. Our Product Main Products: Wastewaster treatment equipment: screw press sludge dewatering machine,dissolved air flotation,MBBR media,disc fine bubble aerator,horizontal screw dehydrator,continuous sludge dryer,PE drum dosing device,full-automatic dosing device,clarifier,rotary drum screen,mechanical bar screen etc. Waste gas treatment equipment: spray tower, biological trickling filter box, FRP fan,biofiltration for VOCs and odors abatement Product Application Business Scope Industry Wastewater Treatment Plant Fishmeal processing plant Fish processing plant Oil refinery Slaughtering plant Diary plant Chemical plant Textile plant Electroplate plant Foundry blacking plant Stainless steel/Aluminum manufacturing plant Odor/VOCs Abatement Plant Washing Scrubbers Active carbon absorber Biofilter Wastewater treatment plant(WWTP/SWTP) Fishmeal plant Feeds processing plant Poultry house Barns Animal manure storage WTP equipment MBBR Bar screen Dissolved Air Flotation Unit Clarifier Disc aerator Tube aerator Air blower Screw press sludge dehydrator Disc dryer sludge dehydrator Chemical dosing tank Lamella Ozone generator Biofilter Washing scrubber Active carbon absorber Our Service The company has a rigorous style, skilled after-sales service team, to provide users with fast and thoughtful service. The company's technical guidance team is a team with many years of technical experience, and is able to complete projects with high efficiency and quality. We rely on the deep understanding of each local country: with years of accumulated deep solid technology and construction ability, to provide you with the whole process of service from design, installation planning, repair to maintenance.Customized Multi-disc Screw Press Dehydrator website:

http://www.bioetp.net/Customized Multi-disc Screw Press Dehydrator Our History Wuxi Qiuyuan Environmental Engineering Co., Ltd, locating in China Environmental Town, Yixing city, is a specialized in designing, installation and commissioning full project for industry wastewater treatment, sewage water treatment and odorous air (VOCs) abatement solutions. Our Factory Wuxi Qiuyuan Environmental Protection Engineering Co., Ltd. Brand is Bioetp ,Specializes in the engineering design and equipment manufacturing of industrial wastewater and waste gas treatment, and provides customers with stable, economic and low energy consumption solutions. Located in Yixing City, Jiangsu Province, China's environmental protection city, Bioetp specialized screw press sludge dewatering machine manufacturer, and provides installation, commissioning and operation services for customers. Bioetp has established cooperative relations with domestic well-known universities such as Zhejiang University and Nanjing University of technology to provide customers with continuous and reliable technical support and solve various difficult and miscellaneous problems of environmental protection. Bioetp combines the latest technology and rich experience to create high-quality, durable, energy-saving and efficient products for customers. Our Product Main Products: Wastewaster treatment equipment: screw press sludge dewatering machine,dissolved air flotation,MBBR media,disc fine bubble aerator,horizontal screw dehydrator,continuous sludge dryer,PE drum dosing device,full-automatic dosing device,clarifier,rotary drum screen,mechanical bar screen etc. Waste gas treatment equipment: spray tower, biological trickling filter box, FRP fan,biofiltration for VOCs and odors abatement Product Application Business Scope Industry Wastewater Treatment Plant Fishmeal processing plant Fish processing plant Oil refinery Slaughtering plant Diary plant Chemical plant Textile plant Electroplate plant Foundry blacking plant Stainless steel/Aluminum manufacturing plant Odor/VOCs Abatement Plant Washing Scrubbers Active carbon absorber Biofilter Wastewater treatment plant(WWTP/SWTP) Fishmeal plant Feeds processing plant Poultry house Barns Animal manure storage WTP equipment MBBR Bar screen Dissolved Air Flotation Unit Clarifier Disc aerator Tube aerator Air blower Screw press sludge dehydrator Disc dryer sludge dehydrator Chemical dosing tank Lamella Ozone generator Biofilter Washing scrubber Active carbon absorber Our Service The company has a rigorous style, skilled after-sales service team, to provide users with fast and thoughtful service. The company's technical guidance team is a team with many years of technical experience, and is able to complete projects with high efficiency and quality. We rely on the deep understanding of each local country: with years of accumulated deep solid technology and construction ability, to provide you with the whole process of service from design, installation planning, repair to maintenance.Customized Multi-disc Screw Press Dehydrator website:http://www.bioetp.net/